Anhui Fanchang Qingbai Wares

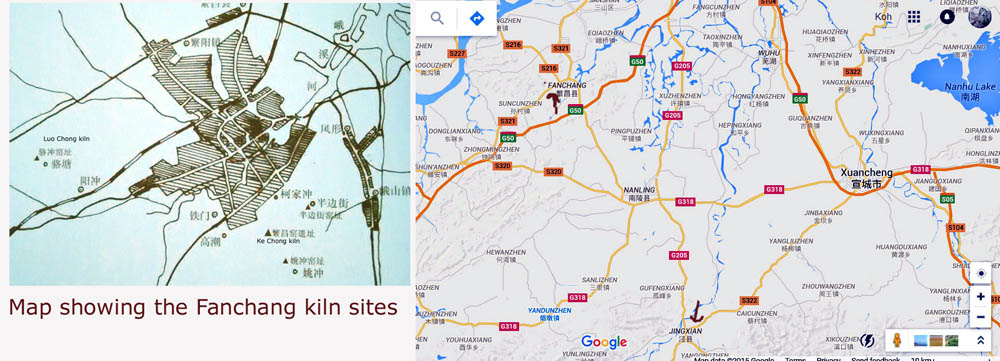

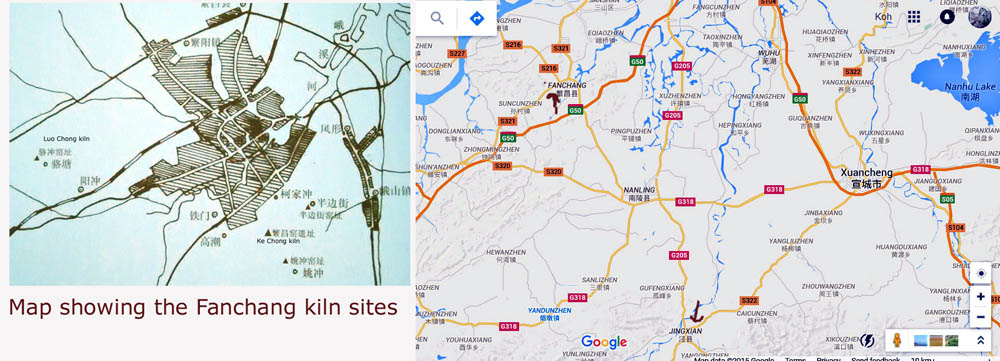

Fanchang kilns are now widely recognised as one the the

earliest sites to produce qingbai wares. Fanchang is one of the county

administered by Wuhu (芜湖), a

prefecture-level city in southeastern

Anhui

province. The kiln sites are located on the southern and western hilly

suburb of the city. From archaeological surveys, it has been established

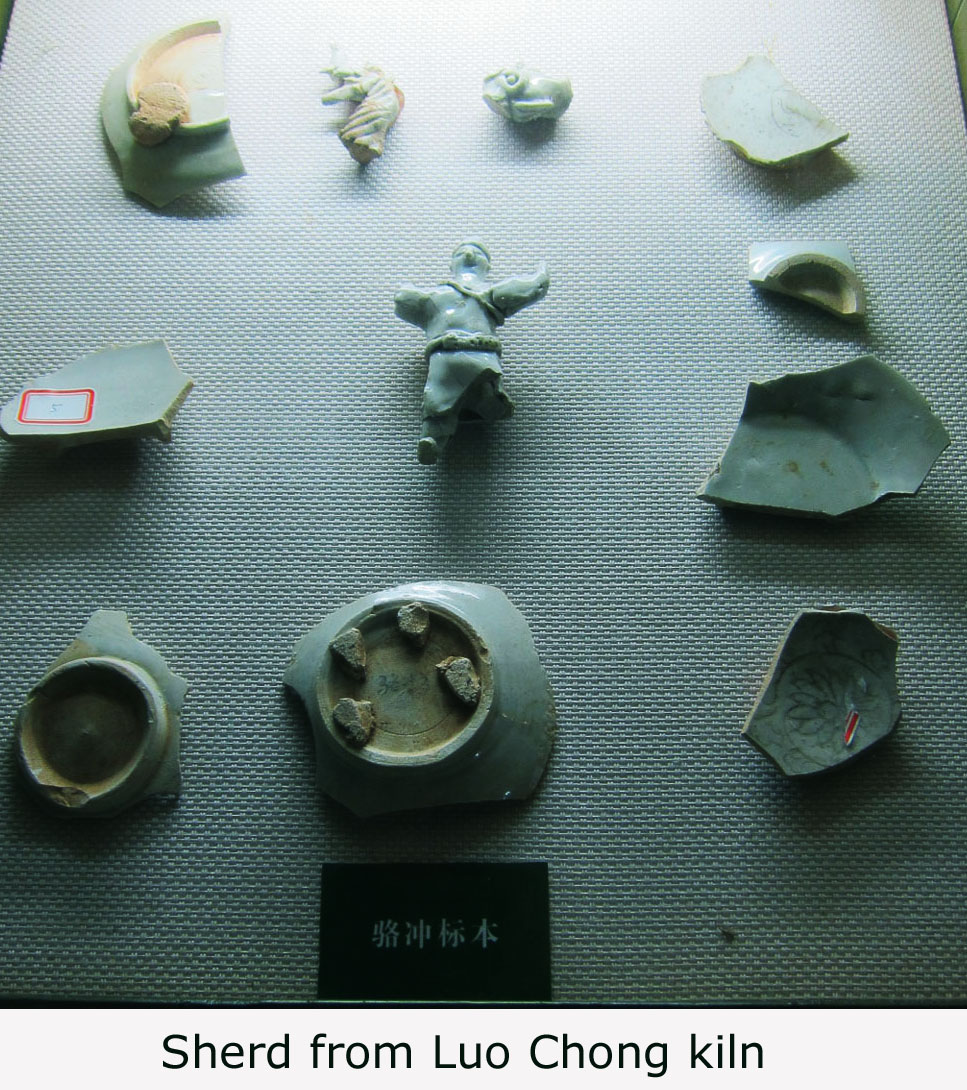

that Luo Chong (洛冲窑) kiln (discovered in the 1980s) on the west may be one of the earliest site. Its

products were widely recognised as the best with smooth glaze and fine paste.

Its scale of production was however small and probably ceased production by end

of 5 Dynasties. The main production sites were located in the south, most

famous kiln being Ke Chong (柯冲窑) (discovered in the 1950s). Although later than that

from Luo Chong kiln, they

also

commenced production in 5 Dynasties, achieved its golden phase during the

early/Mid Northern Song and ceased production by late Northern Song.

The products during the early phase were essentially white glaze

wares but sometime later during the 5 Dynasties, the colour of the glaze

changed. It showed a more distinct pale bluish tone akin to the Jingdezehn

Qingbai glaze. Currently, the earliest known Jingdezhen Qingbai wares were

dated to Northern Song and post dated those from Fangchang. In

the Chinese academic circle, the view that Fanchang and not Jingdezhen was the

pioneer of Qingbai glaze is gaining increasing support.

By the Tang Dynasty, the

production of Chinese ceramics was characterised by green

glaze ware from the South and white from the North. So far,

no kiln were known to produce white ware in the South during

this period. The monopoly over the production of white

wares by the northern China kilns appeared only to be broken

in the 5 Dynasties. The kilns in Anhui in Southern

Chinas could be one of the earliest recipients of the new

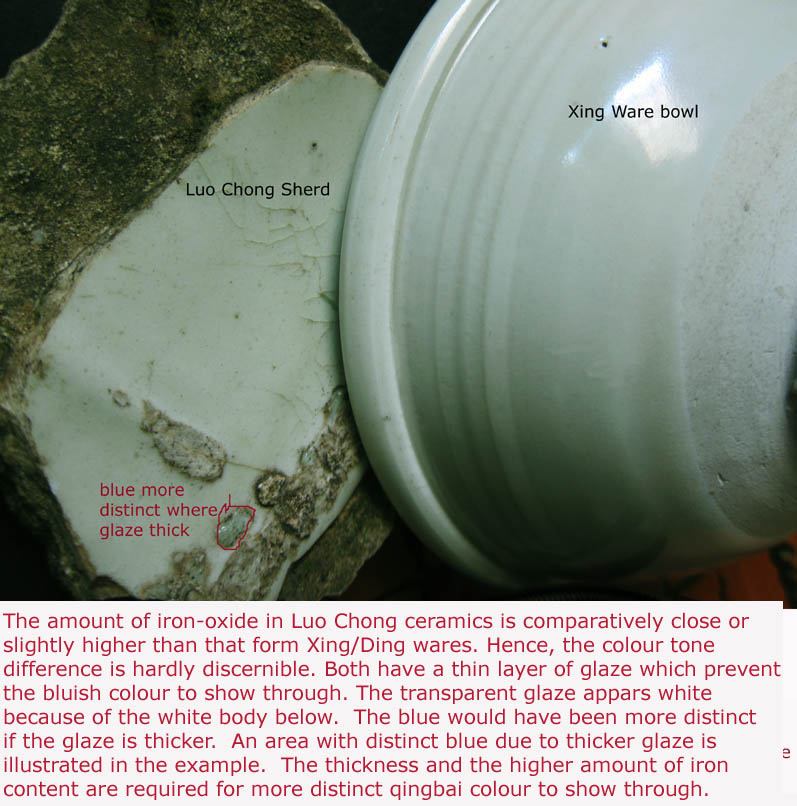

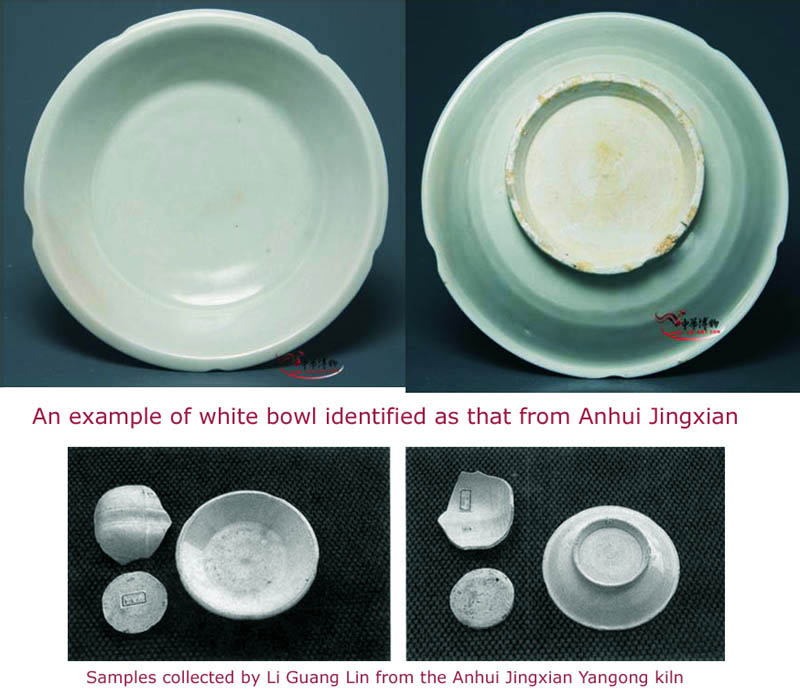

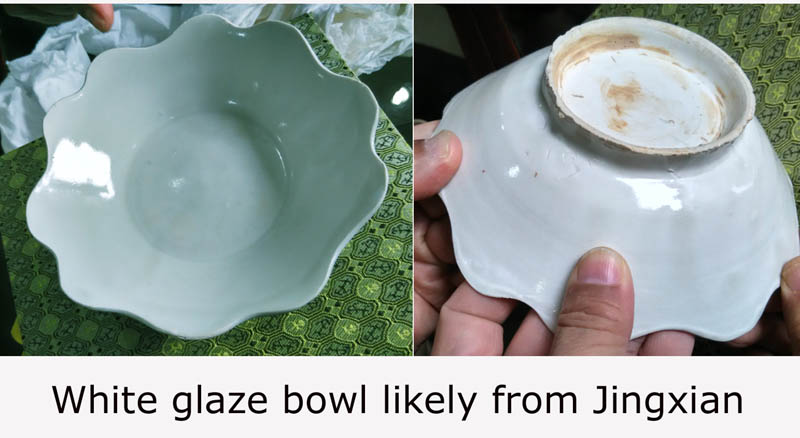

technology. Besides Fanchang, white wares were

also found in

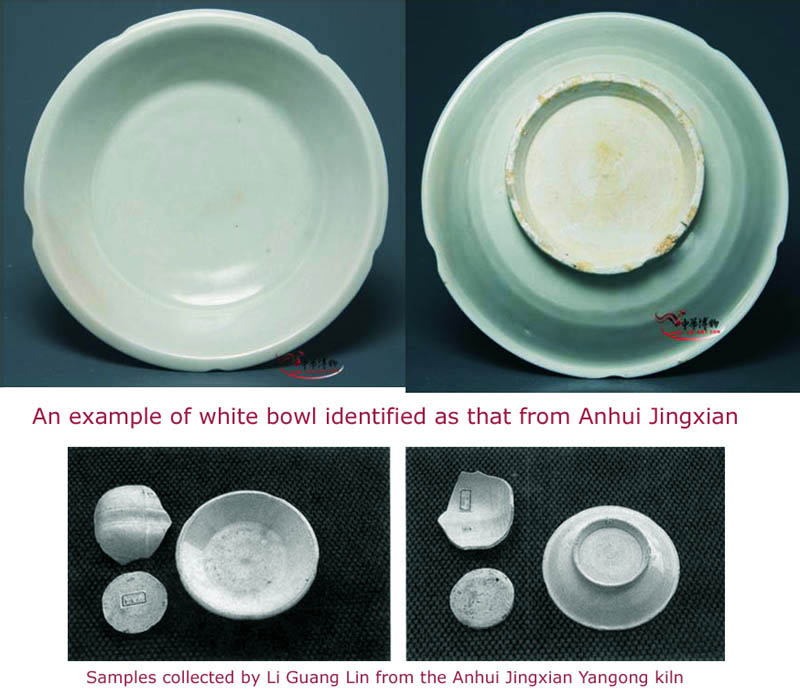

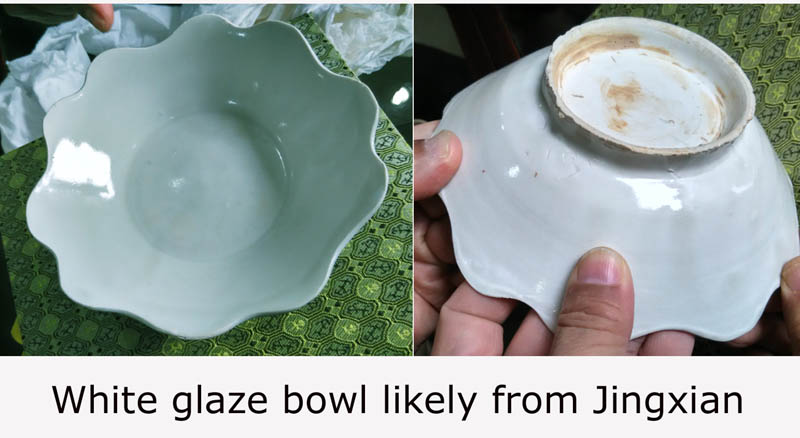

Anhui Jingxian Yangong kiln (安徽泾县晏公窑). Indeed

without comparison,

the white glaze from the Anhui kilns could be visually similar to those produced in

Xing/Ding kiln. But the paste of

the body of those from Anhui is different and not as fine grained as that of

Xing/Ding ware. Bowls/plates similar to those from the

Xing/Ding kilns were produced. There is

however discernible differences in treatment of the

foot.

During the late Tang Dynasty and 5 Dynasties period, Central China

(中原) which included Hebei and Henan was in constant state of severe social upheaval.

Since the ancient past, this was the political centre of

China and any party aspiring to rule China would have to

take control of that region. During the 5 Dynasties,

it resulted in 5 dynastic changes within a short span of

about 50 years. The constant war disrupted economic

activities and hence the livelihood of the people. Many

were forced to flee and migrate to the South. Among them

were potters who brought with them the skill and technology

of porcelain production. In 1996, two archaeologists Zhang

Yong (张勇) and Li Guang Ning (李广宁) from Anhui attended the

Annual Ancient Ceramics Society Conference in Fujian

Jianyang (福建建阳). They brought along some white shards which were

excavated from Anhui Jingxian Yangong kiln (安徽泾县晏公窑). This

triggered renewed interest in the study of Xuanzhou (宣州) white ware.

Xuanzhou was located in present day Anhui. It was mentioned in

Jingdezhen Tao ge (景德镇陶歌), a Qing Jiaqing/Daoguang text which recorded

poetic verses related to porcelain production. The writer had stayed

in Jingdezhen and gathered those information from potters who held collective memory of matters related to porcelain production

passed down orally by their ancestors. According to Li Guang Ning, he

interviewed the villagers who stayed near Yangong kiln. He gathered

that their ancesters were from Northern China. Many of the white wares

from the Cirebon shipwreck showed characteristics

similar to that from the Jingxian kiln.

Although the local potters adopted the technology for

white ware, the wares were still fired in traditionally Southern China dragon

kilns. During the initial phase, the potters also made fully glazed

bowls/dishes that were not found in Northern White wares. To ensure the

vessel did not adhere to the base of saggar, clay lumps were placed on the foot

as separator. This was a stacking method adopted from Zhejiang Yue

potters. However, the Fanchang potters also

adopted the use of disc or ring as support for vessel and saggars similar to

that from Northern kiln.

In the Chinese Ceramics circle, some classified

Fanchang as Xuanzhou wares. Li Guang Ning (李广宁)

however disagreed and pointed out that administratively Fanchang was not under

the jurisidication of ancient Xuanzhou except for short span during its history. However, it is likely that

ceramics wares from Fanchang were used by the palace of Southern Tang (南唐) (937

- 976 A.D). The capital was located in Nanjing in Jiangsu Province.

It ruled the territory that comprised parts of modern Fujian, Jiangsu and Anhui

provinces and the whole of Jiangxi Province. Some Fanchang Qingbai wares

were found in the tombs of the first two South Tang ruler. However, they

are unlikely produced by an official kiln administered by the court. Fanchang ceramics

were folk kiln wares sent as tribute to the court.

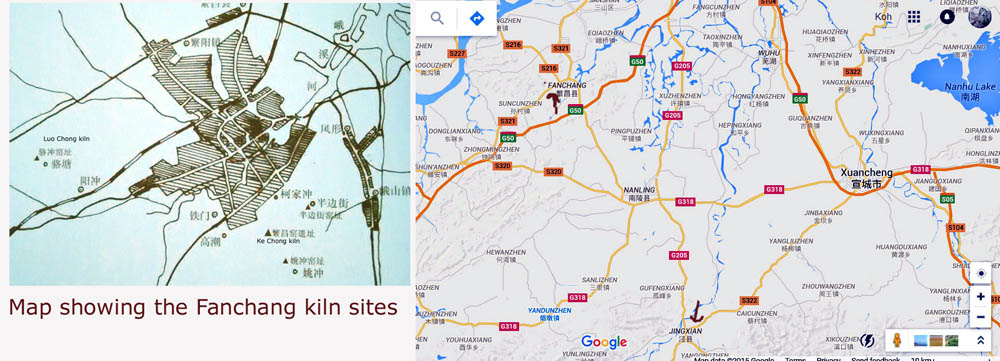

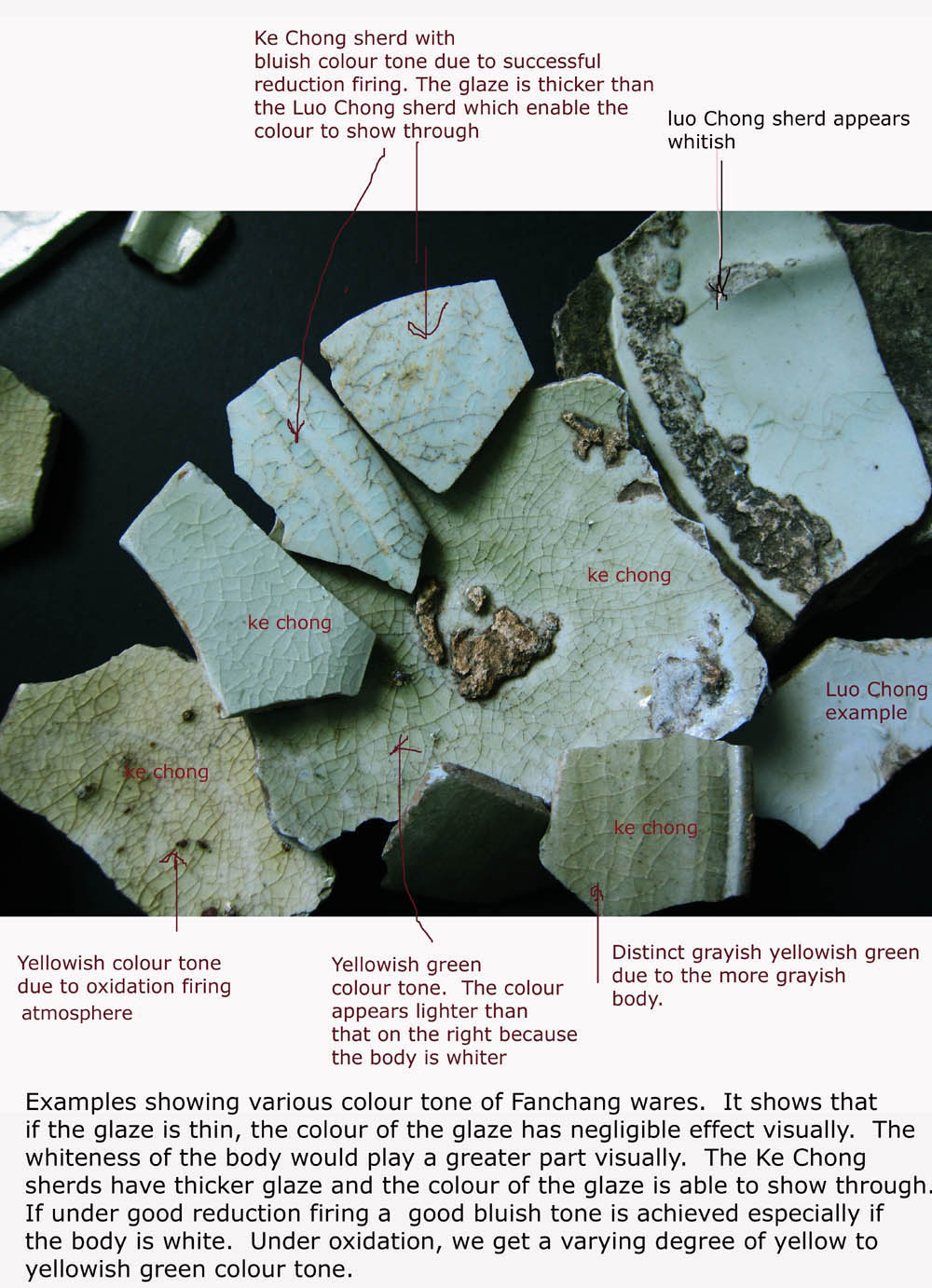

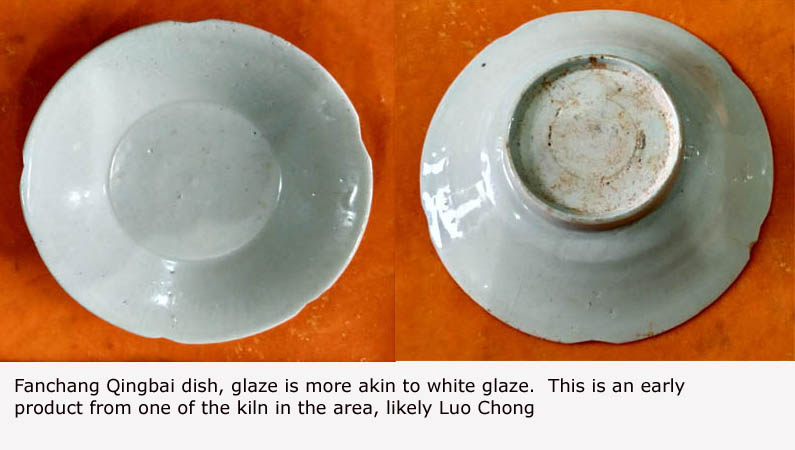

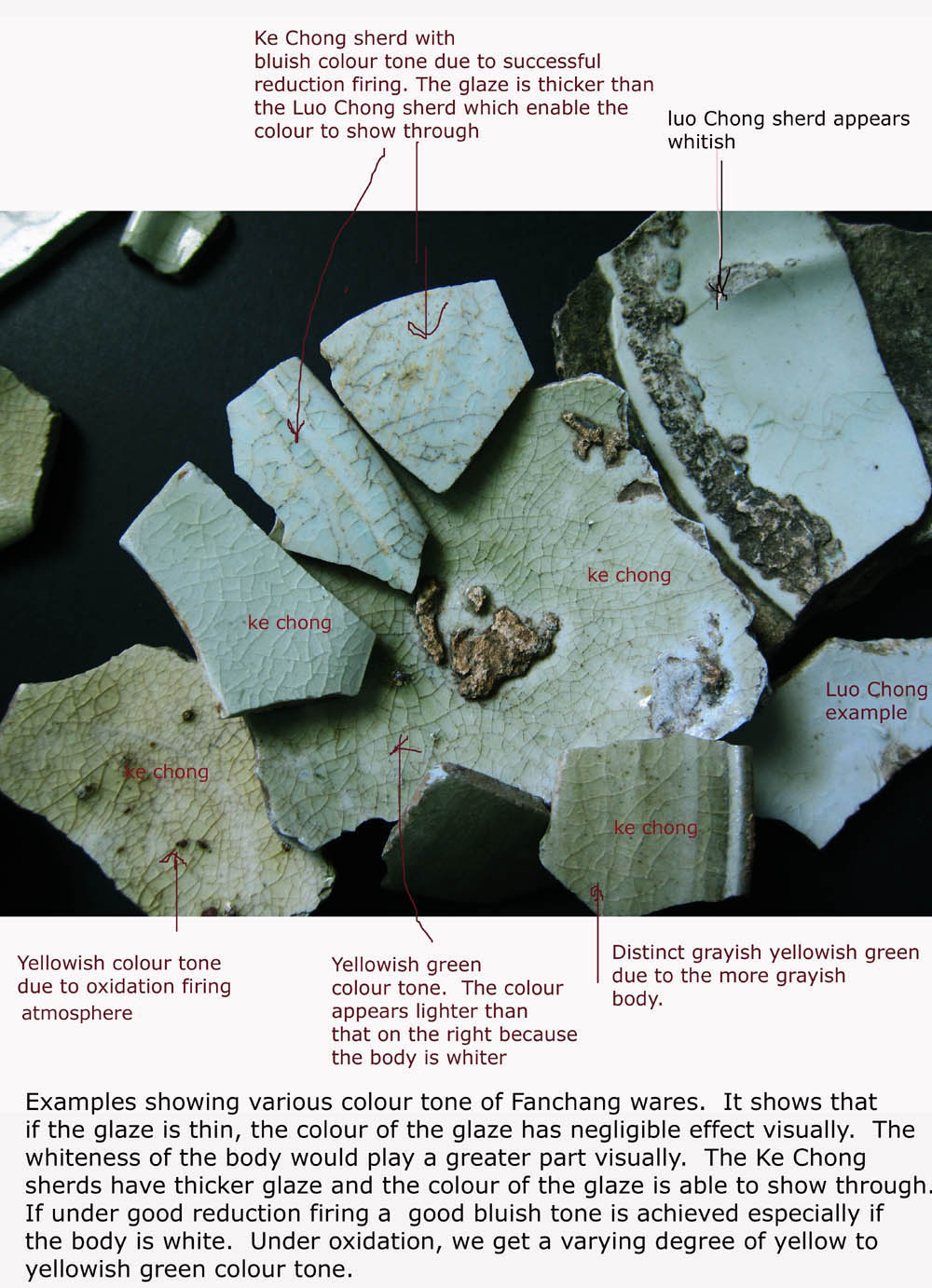

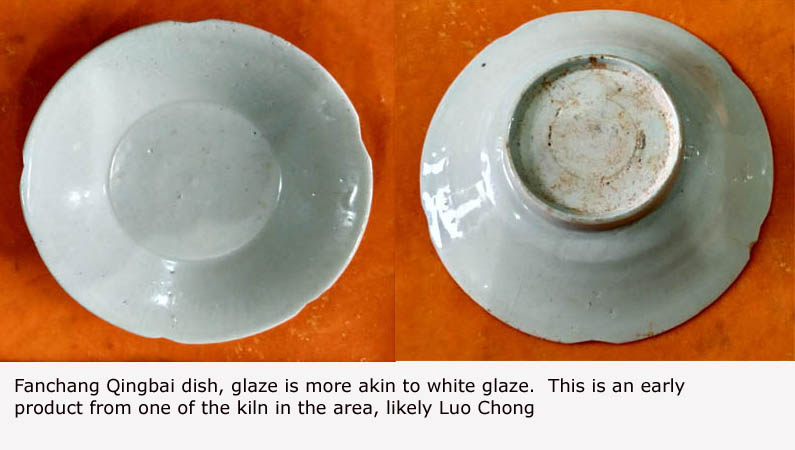

Strictly speaking, the early Fanchang wares typify by those from Luo Chong kiln

were more akin to white wares. The amount of iron-oxide content in Luo

Chong and glaze composition was scientifically analysed and found to be more

similar to those from Xing/Ding kiln than that from Yue kiln. Comparatively, the

latter Ke Chong glaze was found to contain comparatively higher iron content.

The glaze colour is not apparent if

the thin glaze. However, when the glaze became thicker in the subsequent

products, the iron-oxide exerted its influence. The glaze became a

distinct faint bluish or varying degree of yellowish/yellowish green tone

depending on the firing atmostphere. In short, the glaze visually became what we

associated with qinggbai wares. Hence, two important factors for

qingbai is thicker and sufficient iron oxide in glaze. It would then

appears that the qingbai glaze of Fanchang wares evolved from the early white

glaze.

|

During the early stage, the potters were emulating the white wares of the North.

The potters were likely aware that the glaze could be bluish if of sufficient

thickness. This is apparent in the early products where the glaze pooled

into bluish tone in certain area. Even this phenomenon is not unknown in North

white wares. Hence, it is likely that the Fanchang potters

subsequently intentionally thicken the glaze to produce the qingbai effect. If that was

the case, it must be to meet the aesthetic preference of the consumers.

Indeed, the Chinese ceramics expert Feng Xiang Ming was the first to propound

the view that it was intended to emulate the colour of Jade, a material widely

admired and treasured by the Chinese. However, the opponents held that it

was purely accidental due to the nature of the glaze, ie the inherent higher

iron oxide.

During the 2015 Annual Ancient Ceramics Conference held at Wuhu in Anhui,

certain interesting facts about Fanchang Qingbai were also revealed. Based on scientific analysis of the porcelain material

found near the kiln site, it was discovered that it was low on alumina, only

around 13%. With this low alumina, the vessel would not be strong

enough and collapse during firing. Analysis of the kiln qingbai

samples however showed that the alumina content was 21% to 24%. It

appears that an additional ingredient which provided additional alumina was

added to the local raw porcelain material. This is referred to as the

two-components formula (二元配方) and thought to be introduced only in Jingdezhen

during the Yuan Dynasty. The discovery suggests that Fanchang potters

were the actual pioneers of this innovation. Another interesting

discovery was that the saggars in the kiln have a layer of glaze on the

upper part of the body. It showed that glaze was used to seal the gap

between the saggars to prevent air to enter the saggar which housed the

vessel during firing. This technology was only found to be used on

the saggars for Yue mise wares. From It seems that this added protection

had resulted in lower product spoilage. As a result, comparatively

lesser ceramics rejects/fragments were recovered from the kiln sites.

|

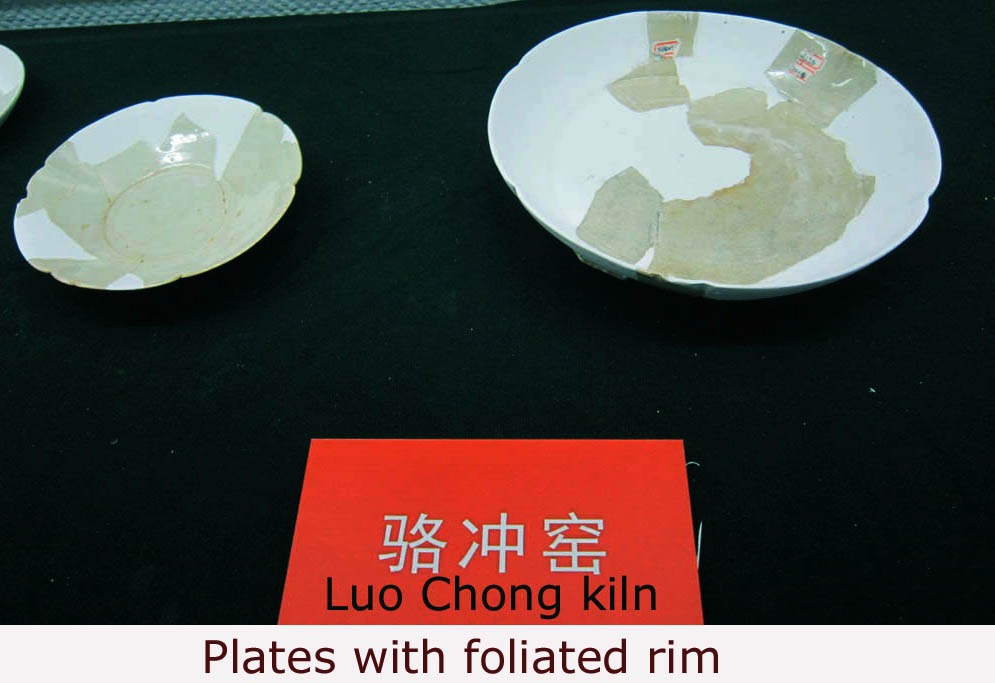

The initial products were greatly influenced by white

wares from Northern China. Those from the early period were of good

quality with those from Luo Chong kiln widely recognised as the best. During

the early phase, the products were essentially white wares. The glaze is thin,

smooth without crazing. But Luo Chong essentially ceased production by

end of 5 Dynasties.

|

|

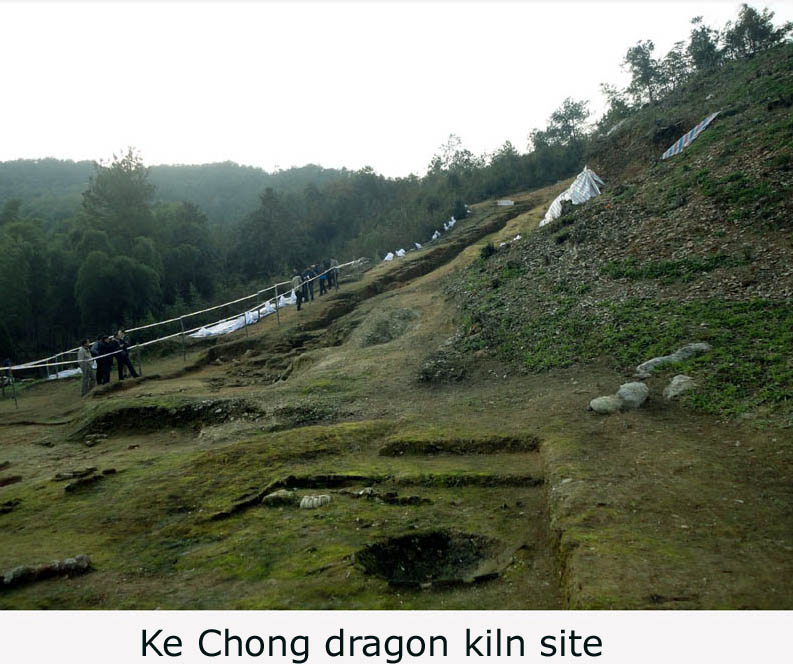

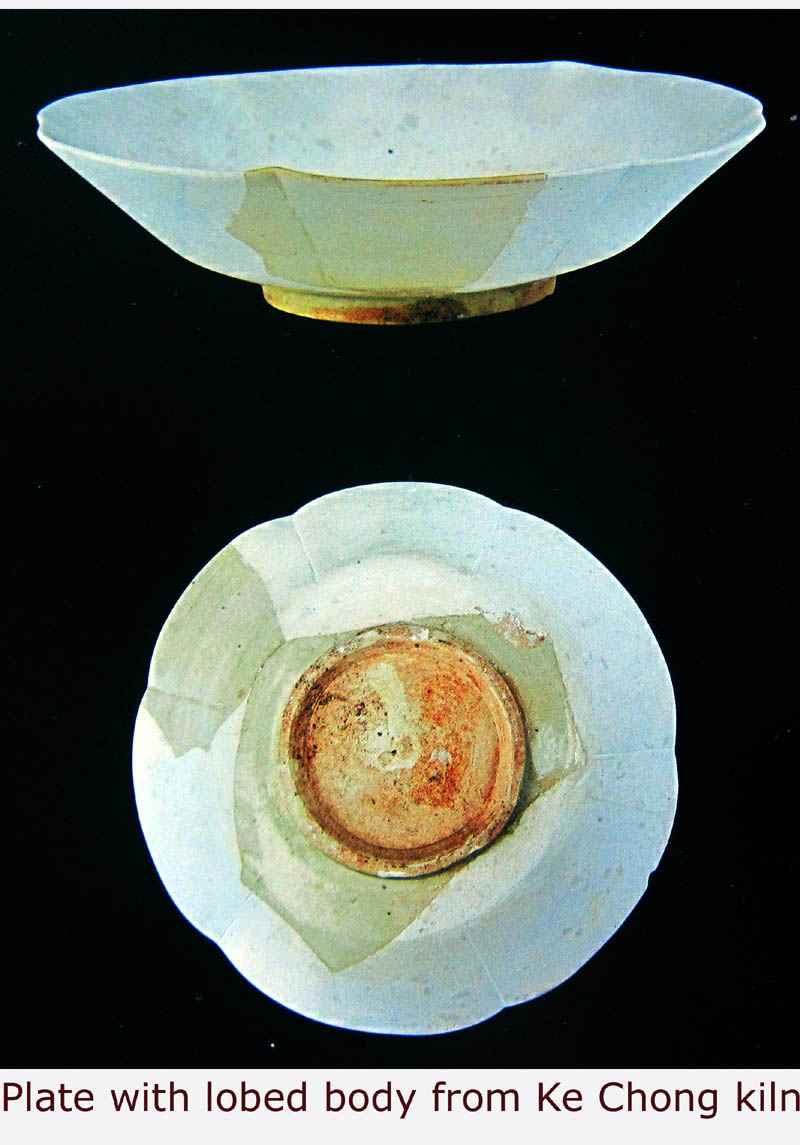

Ke Chong kiln is preserved and currently a park and museum project

is under construction. It is the showcase of Fanchang wares

with a history that spanned the whole production phases of Fanchang

Qingbai wares . At least by the later part of

5 Dynasties, Qingbai wares were produced. Products from this period

till Mid Northern Song represented the golden period of Fanchang

Qingbai. The products were of good quality, with fine white

paste and many have a pleasant light bluish colour tone. After

Mid Northern Song, the quality of the products deteriorated.

The glaze generally displayed a yellowish to yellow green colour

tone. The paste also deteriorated and became more coarse and

grayish in colour. Grayish paste visually imparted an undesirable grayish tone

to the colour of the glaze. Various reasons such as

exhaustion of raw porcelain material, decline of Fanchang commerical

position and stiff competition from the emerging Jingdezhen wares

were suggested to explain the decline and final closure of Fanchang

kilns by the close of Northern Song period.

One distinct characteristic of Fanchang Qingbai is the presence of

fine glaze crazing on majority of the finished products. This

is especially obvious on those underfired products with

yellowish/yellowish green glaze. Glaze crazing is

the result of different expansion rate of the body and the glaze.

The body expanded and contracted faster than the glaze when temperature

changes.

This exerted outward pressure on the coat of glaze and over time

fine crazing developed. Apparently change was made to the

glaze formula to obtain thicker coat of glaze during the

glazing process. As mentioned earlier, thicker glaze is

required for the glaze to show its colour distinctly.

Fanchang kilns produced mainly

utilitarian wares such as bowl, plate, dish, ewer, cover

boxes, incense burner, jar,

scuptural figurines and

etc. Incised/impressed/carved decorative technique was seldom found on Fanchang

qingbai. The most widely used decoration was probably carved lotus petals

on the wall of some vessels. In fact, most of the Fanchang qingbai

were

deliberately left plain. Illustrated below in

chronological order were some of the typical vessels recovered from

graves spanning 5 Dynasties to late Northern Song period.

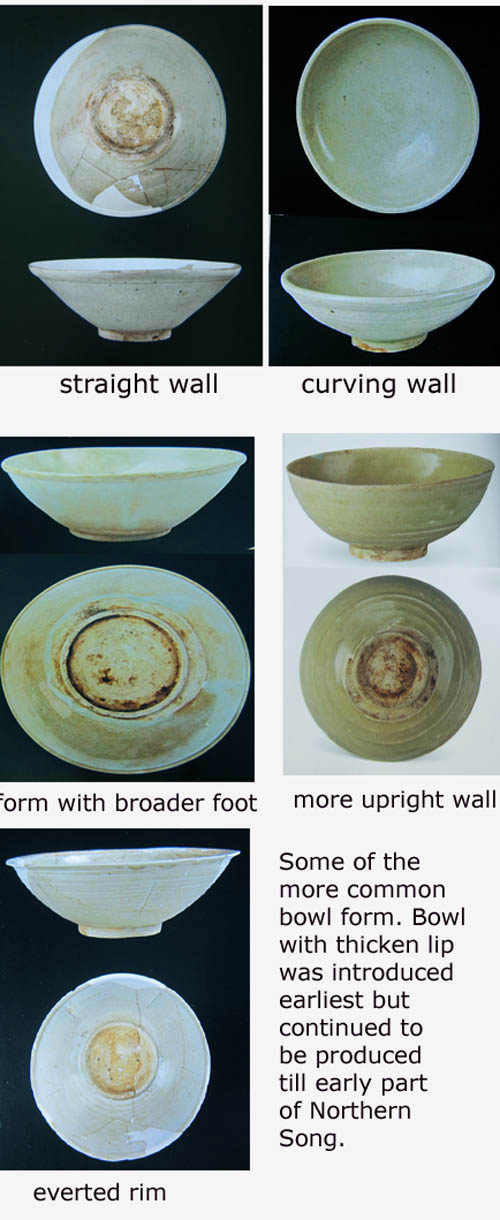

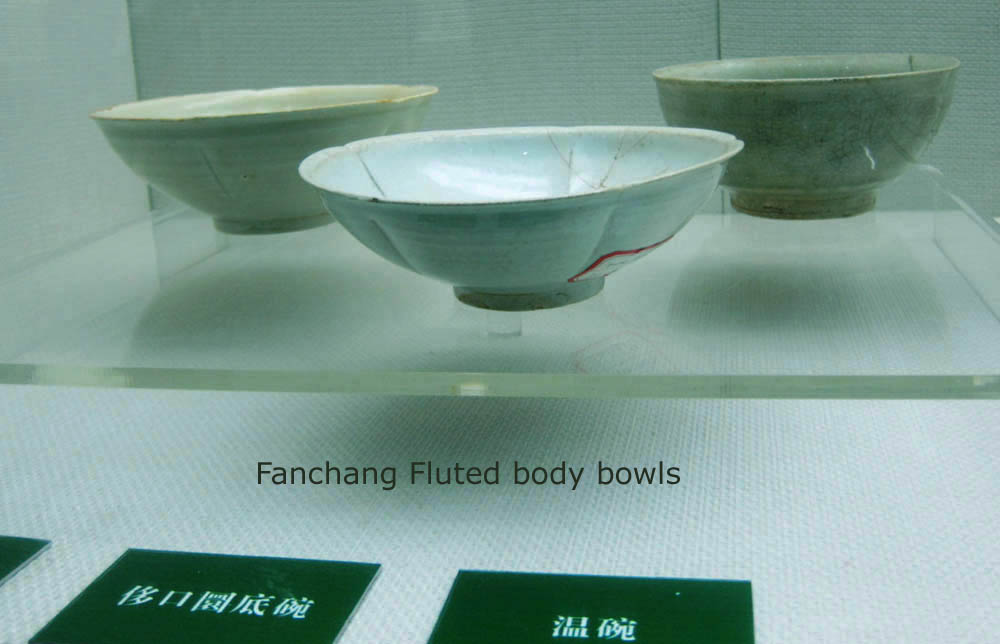

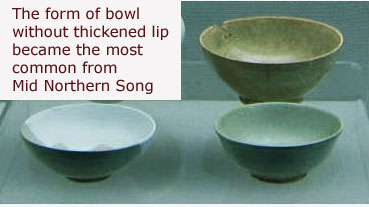

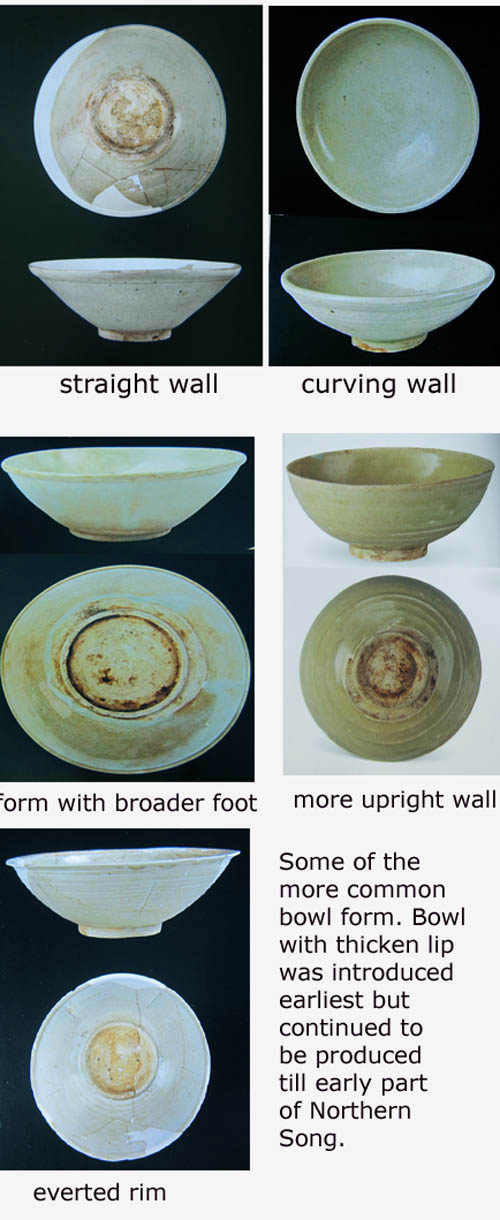

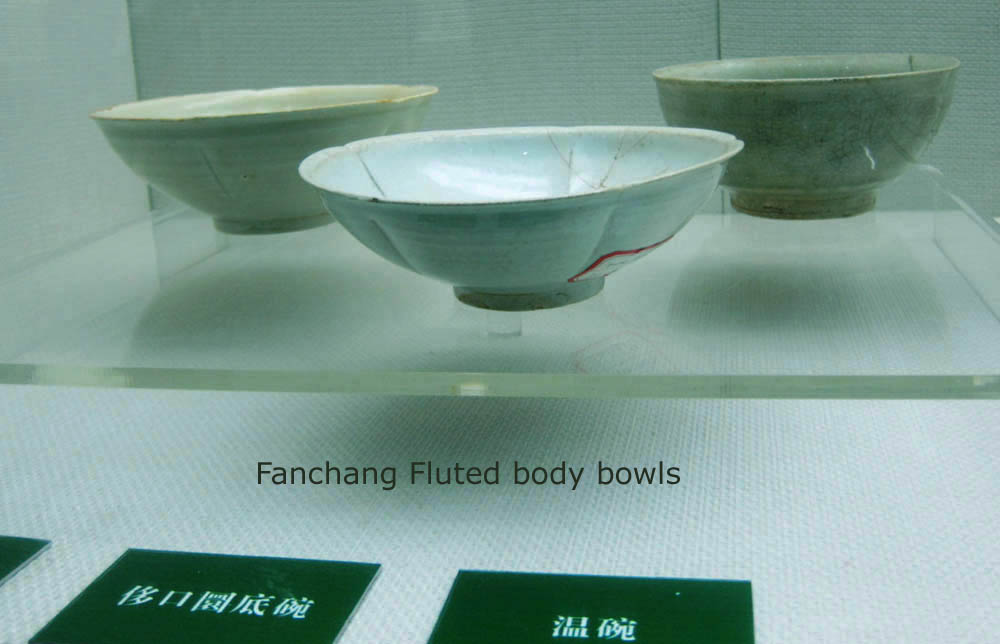

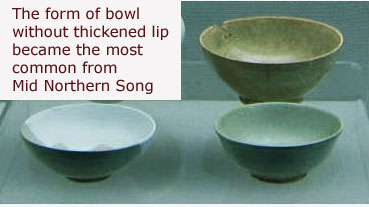

Bowls with thickened lips and those with lobed body and everted rim

featured among the earliest form from this group for vessel. The

earliest typically have more whitish/whitish yellow glaze. Some of

those with thickend lips continued to be produced till around the Mid

Northen Song period. From then on, those with thicken lip became

the mainstream form.

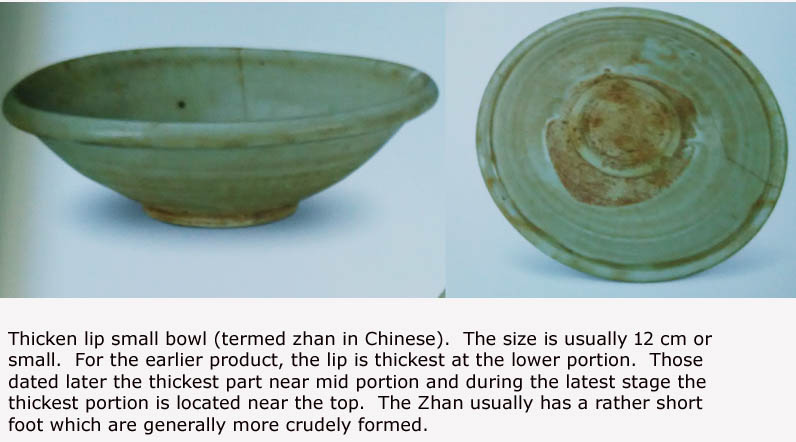

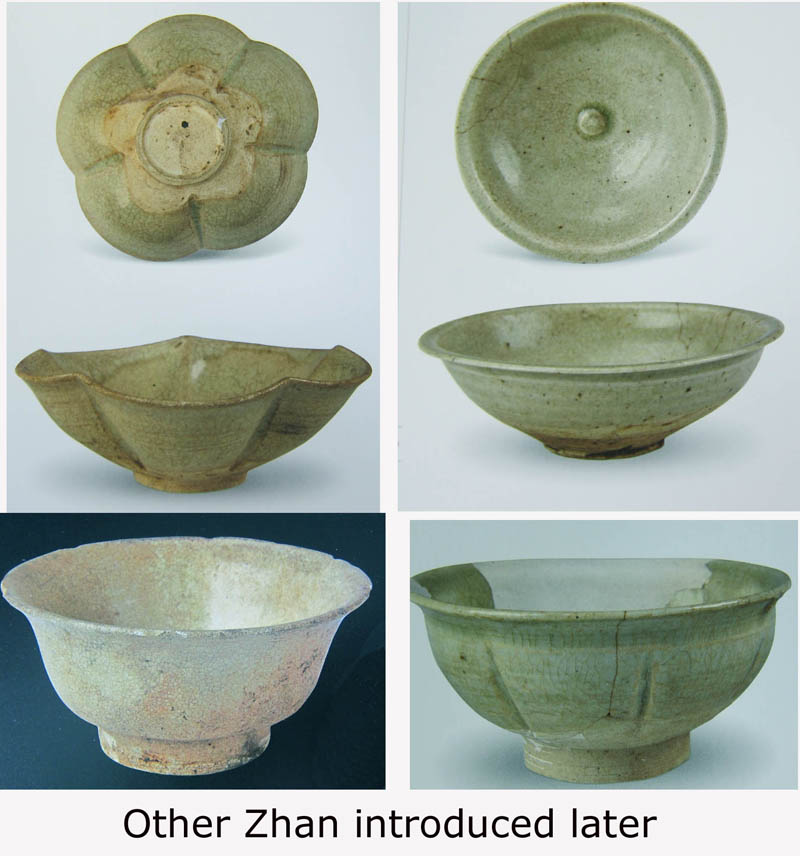

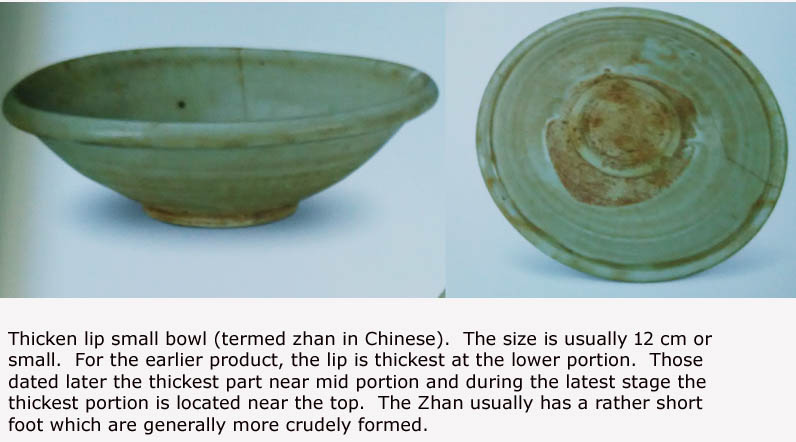

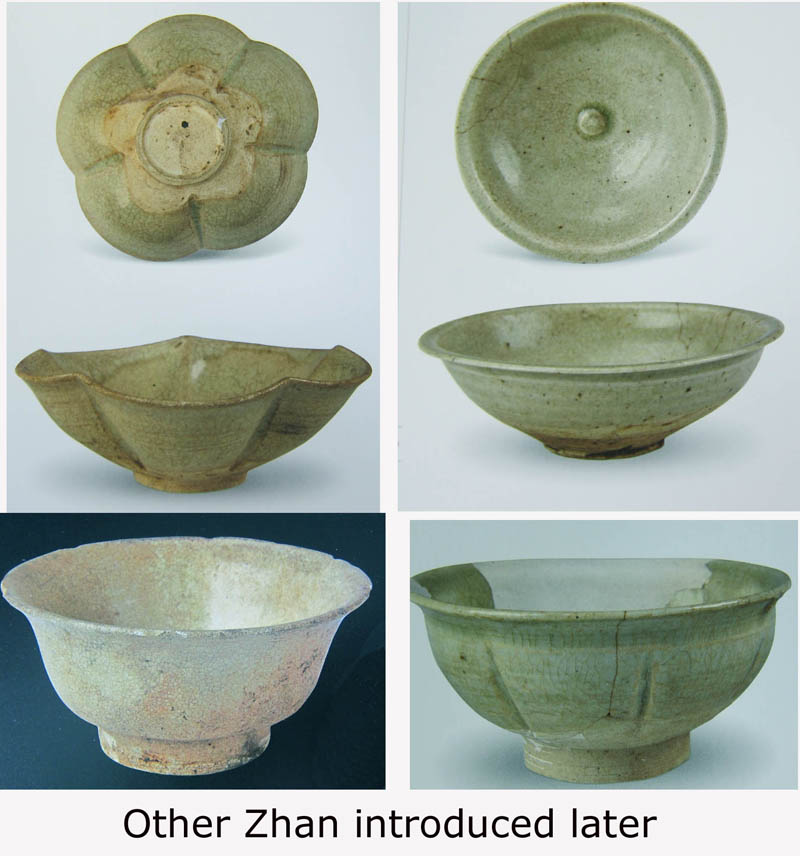

Small bowls (with a dia. 12 cm or smaller) termed Zhan

(盏) in Chinese were also produced in large number. They were used for tea

drinking. The most common form has a thicken lip. During the

Northern Song, there were also other form such as those with foliated body,

everted rim or constricted area below the rim.

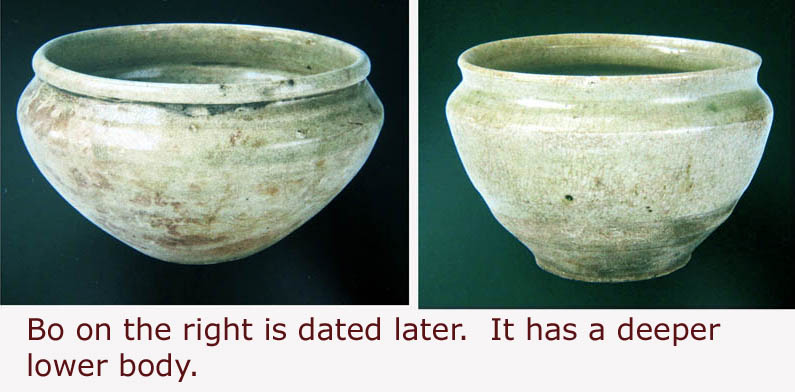

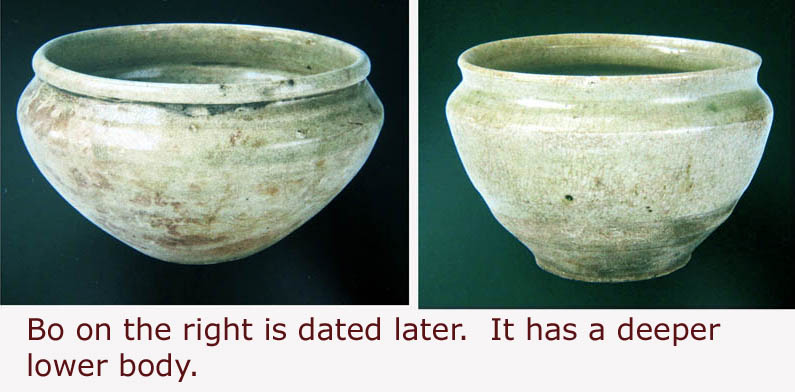

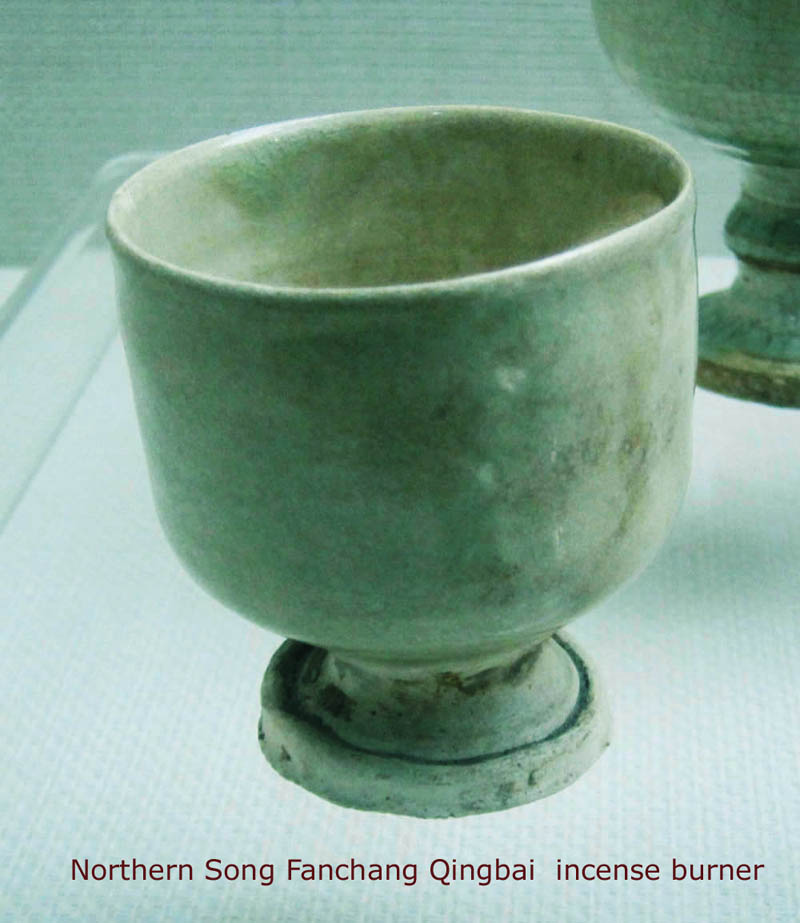

Another common bowl-shaped form is what is term Bo (钵)

in Chinese. Two types existed, one with flat base or recessed base which

appeared first and those with foot introduced around late 5 Dynasties period.

Both types were during the Northern Song period. As compared with those from 5

Dynasties, those produced later have more elongated and deeper lower body.

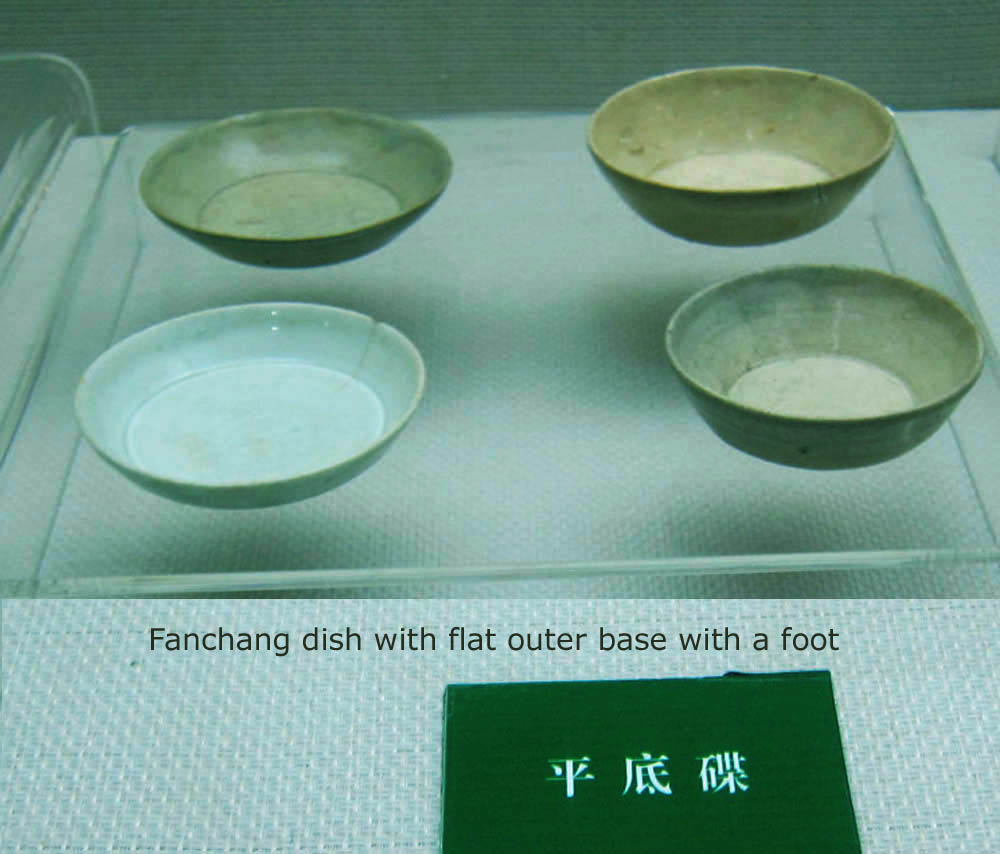

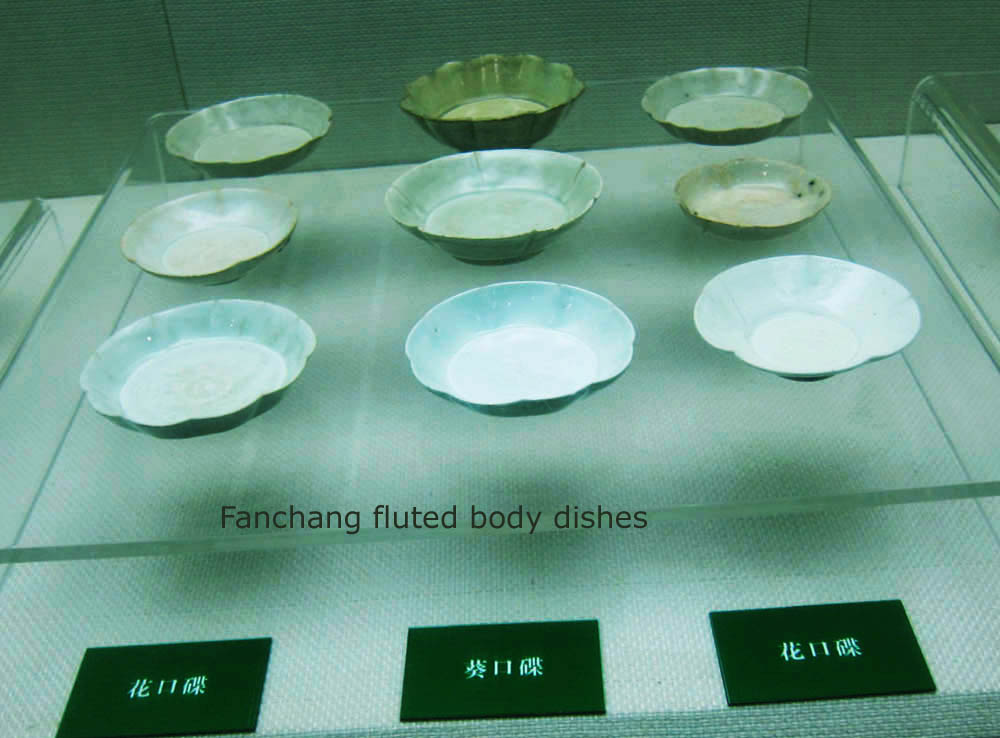

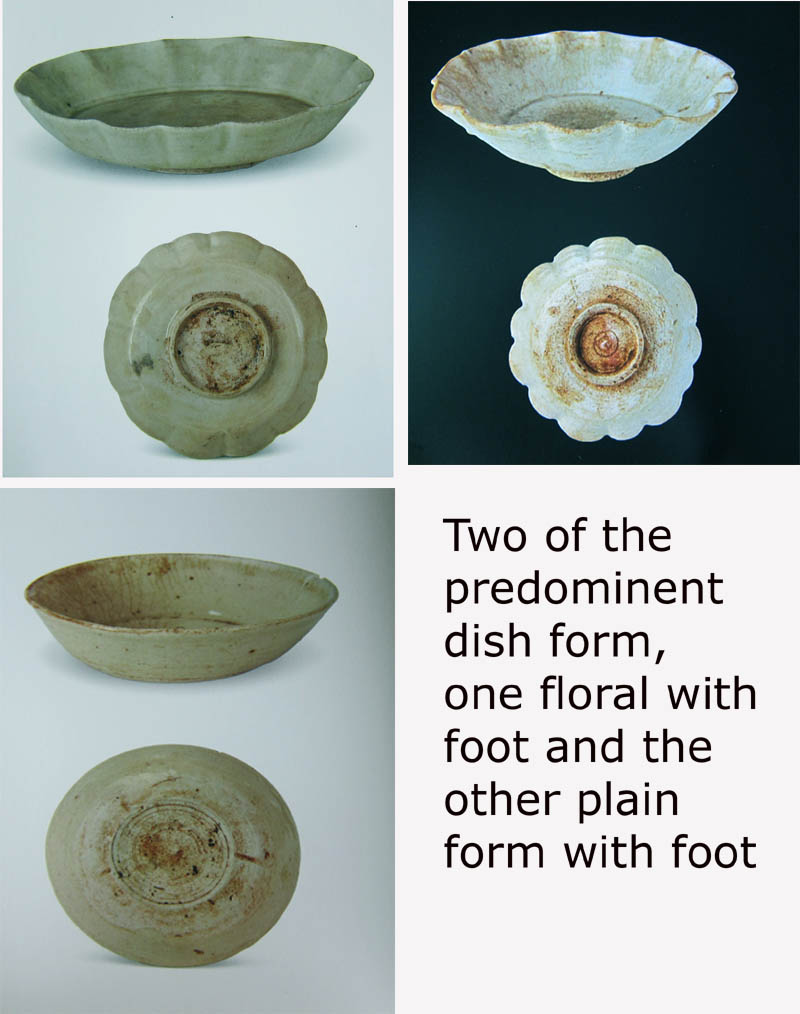

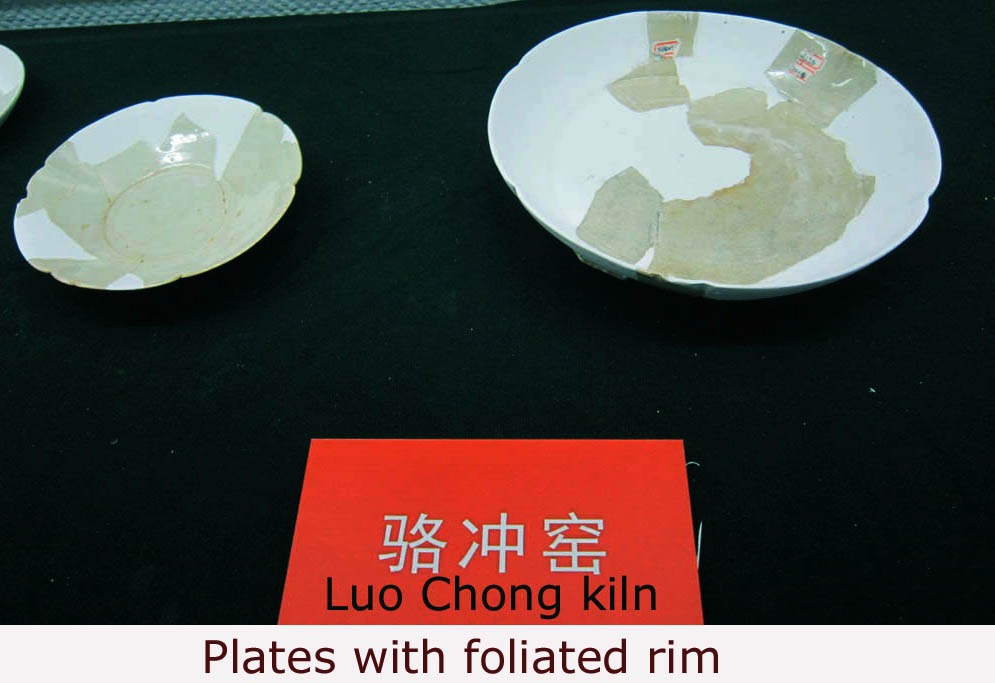

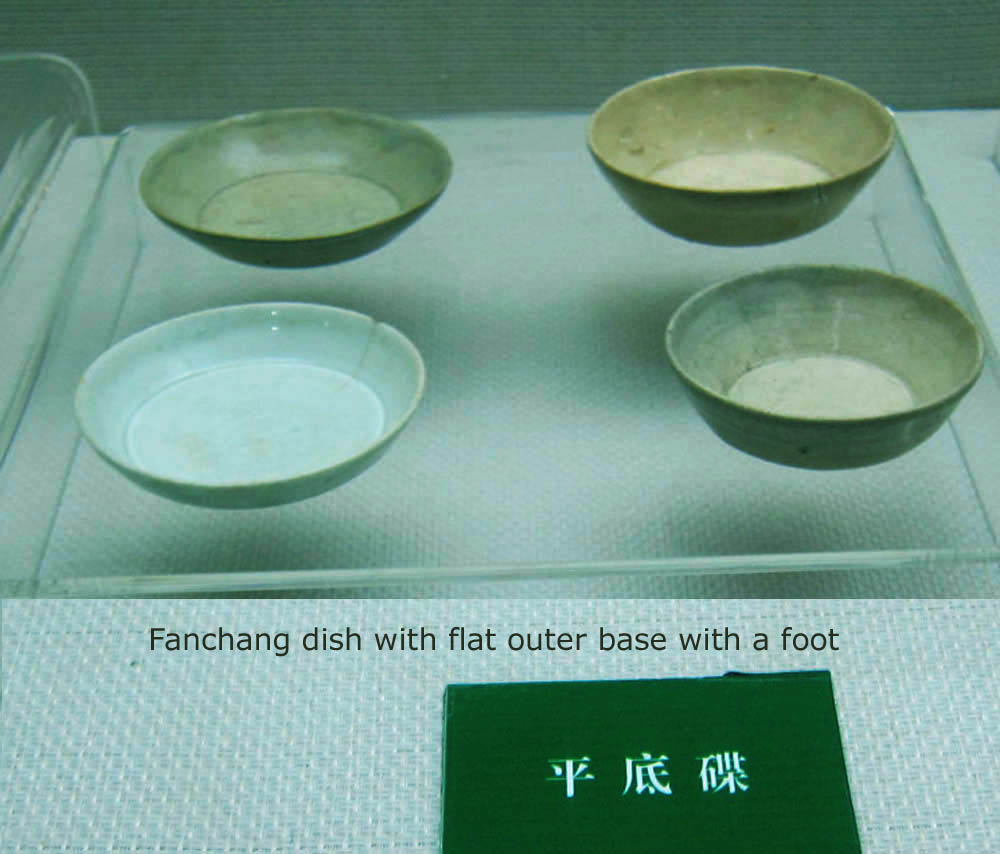

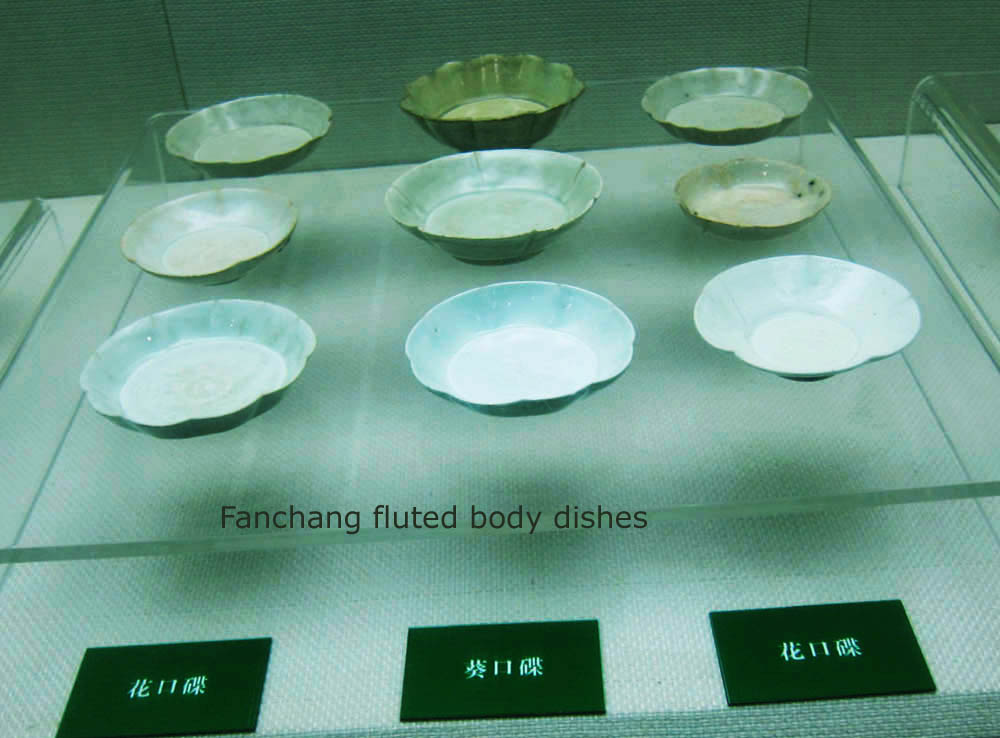

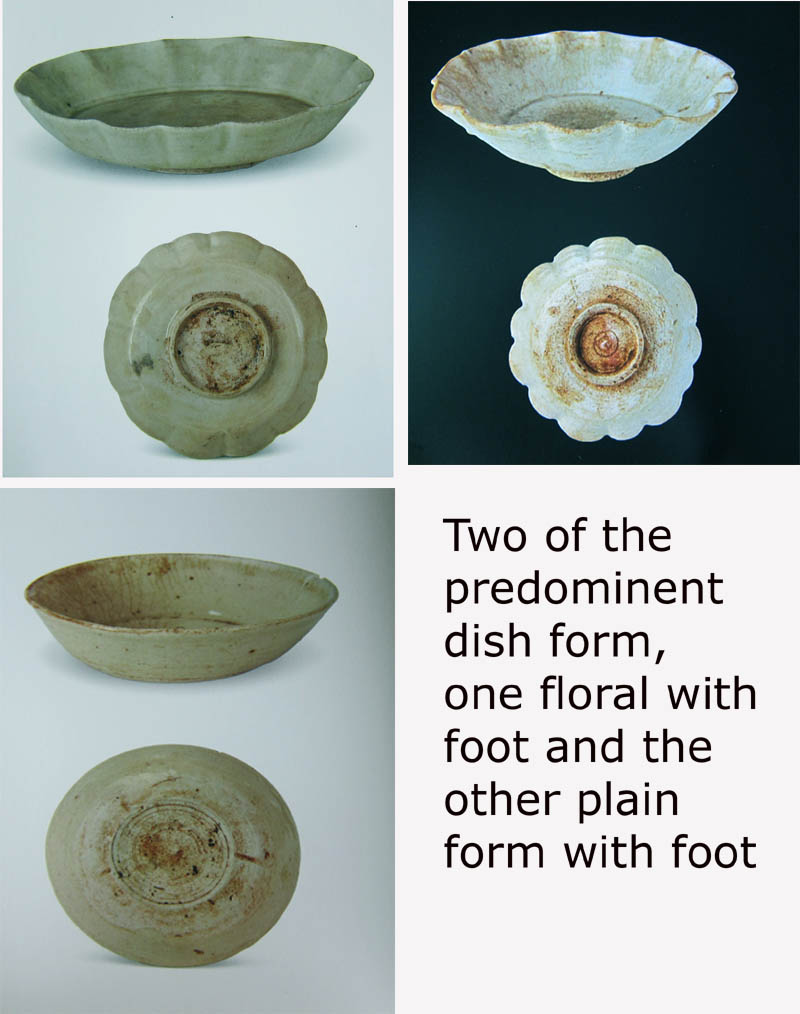

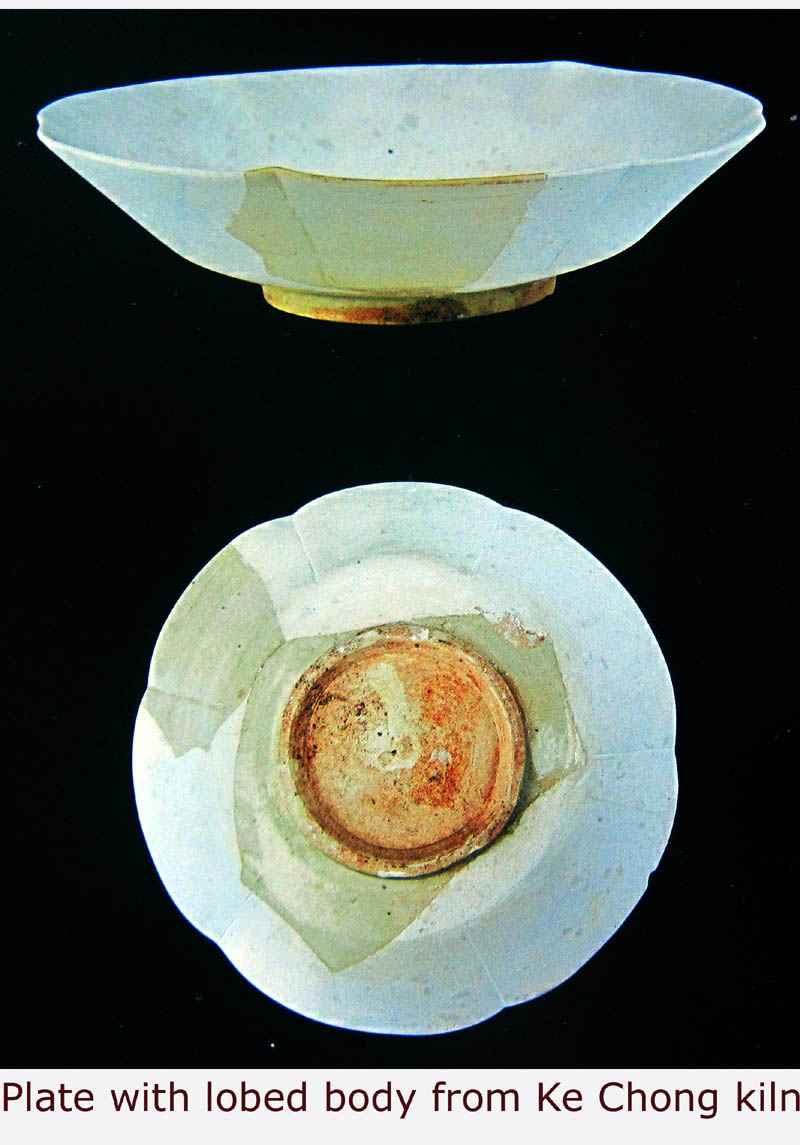

Dish was another category which was produced in large quantity. The

typical one has a dia. of 12 cm or smaller. There were two types, one with

foliated body and the other plain. Those with a plain body have flat base

without foot.

In comparison, plates were found in relatively small

number. The form is rather basic usually with or without

foliated rim.

The most elegant form is probably that with a lobed body.

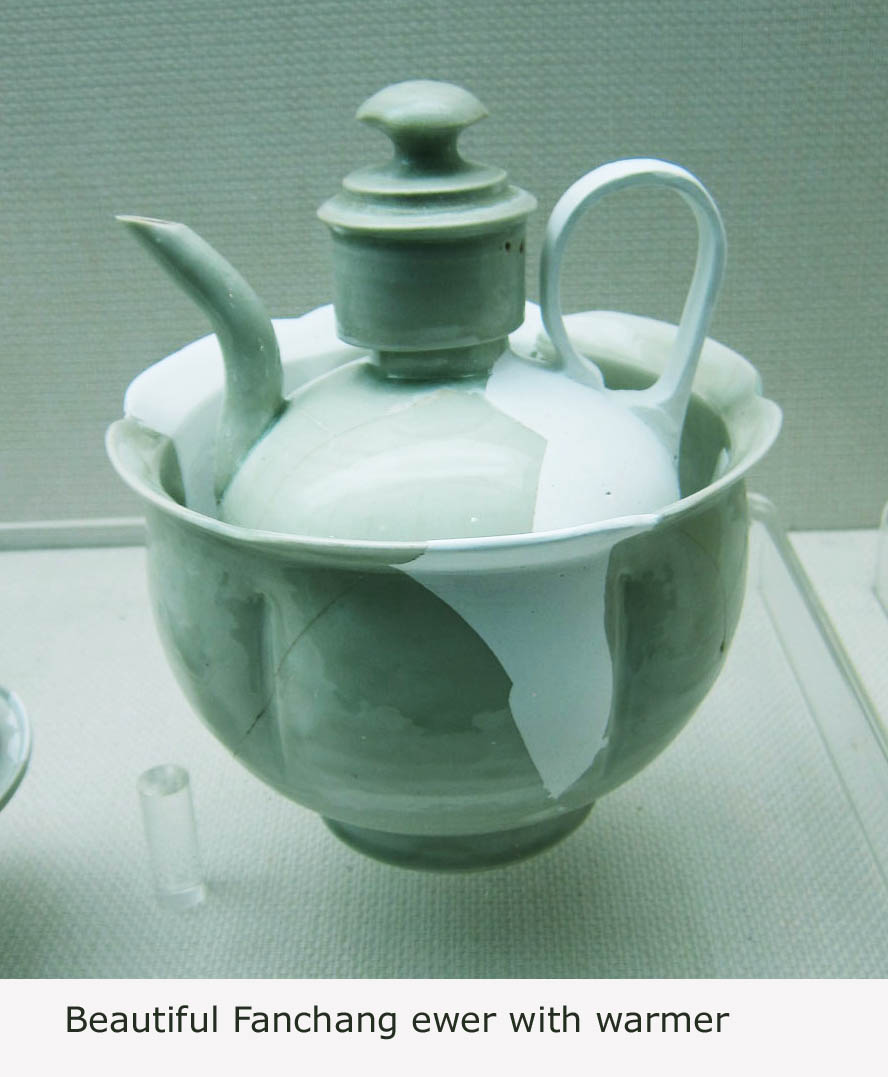

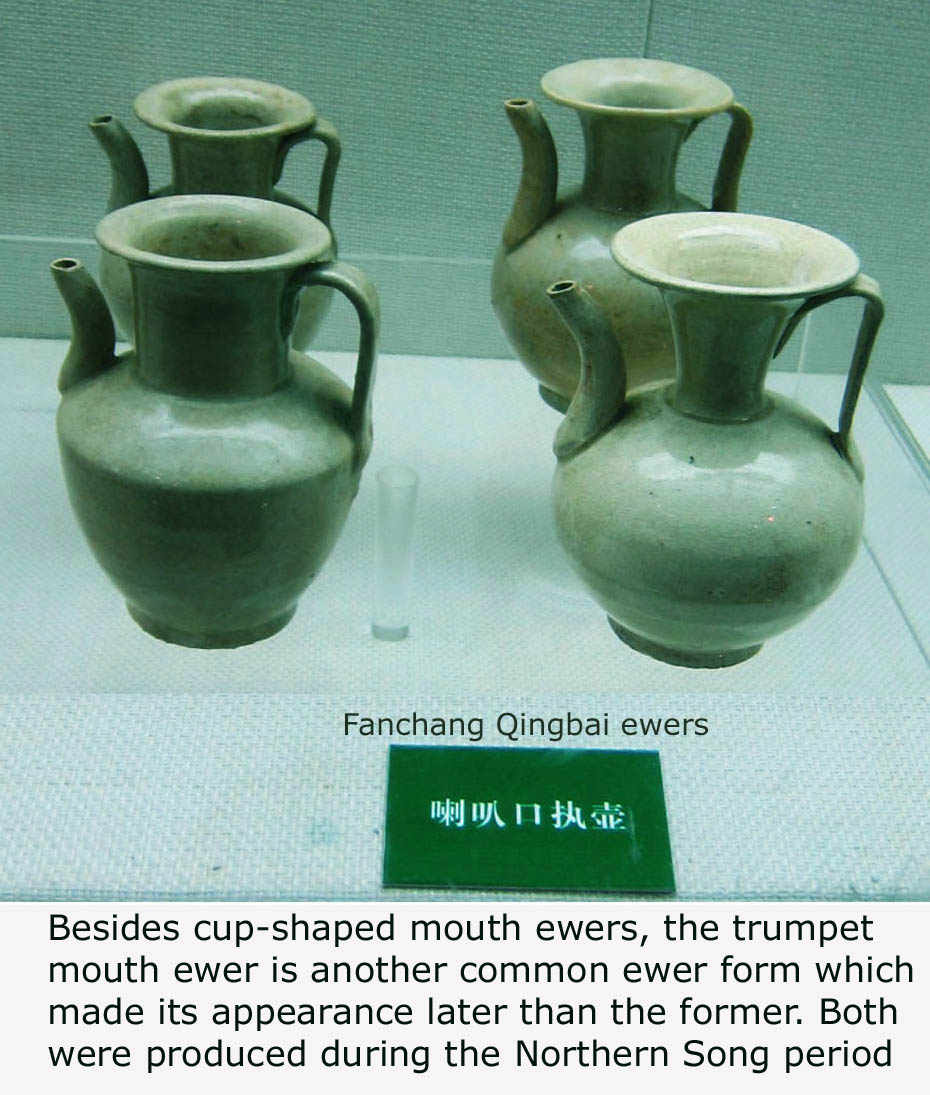

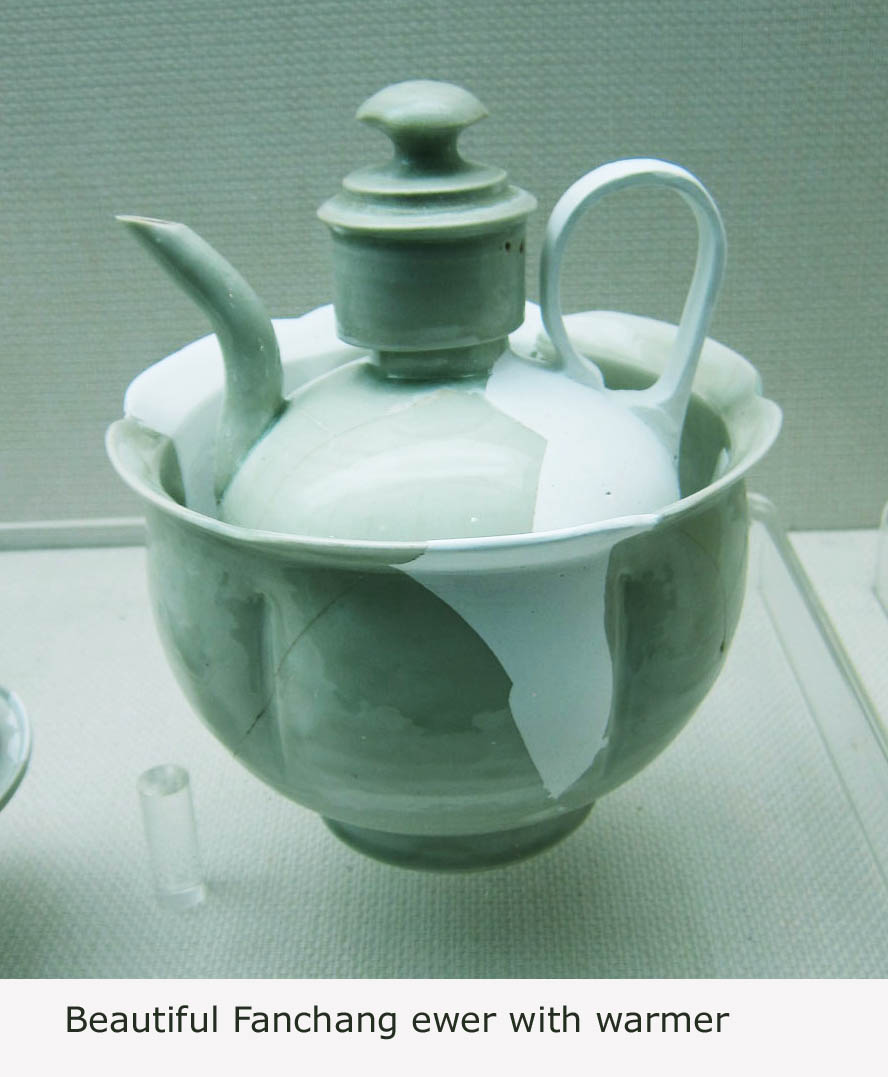

Ewer constituted another important category of product

from Fanchang. There are two types, one with a warmer that was used for

wine drinking and the other without the warmer for tea drinking. The ewer

for wine comes with a cover. This type of ewer was produced from 5

Dynasties till Mid Northern Song period. The bowl shaped warmer has either

plain or lobed body. Fanchang produced large number of such wine vessel

set but the quality is usually usually rather mediocre. Most are rather poorly

finished and usually underfired. There are however some number which are a

good quality such as that illustrated below.

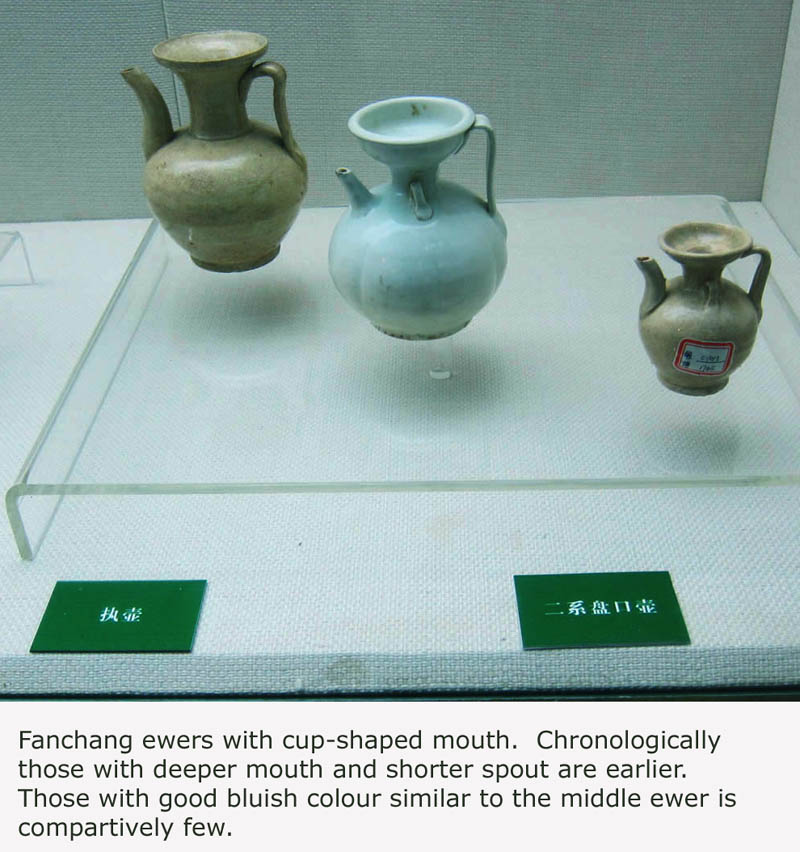

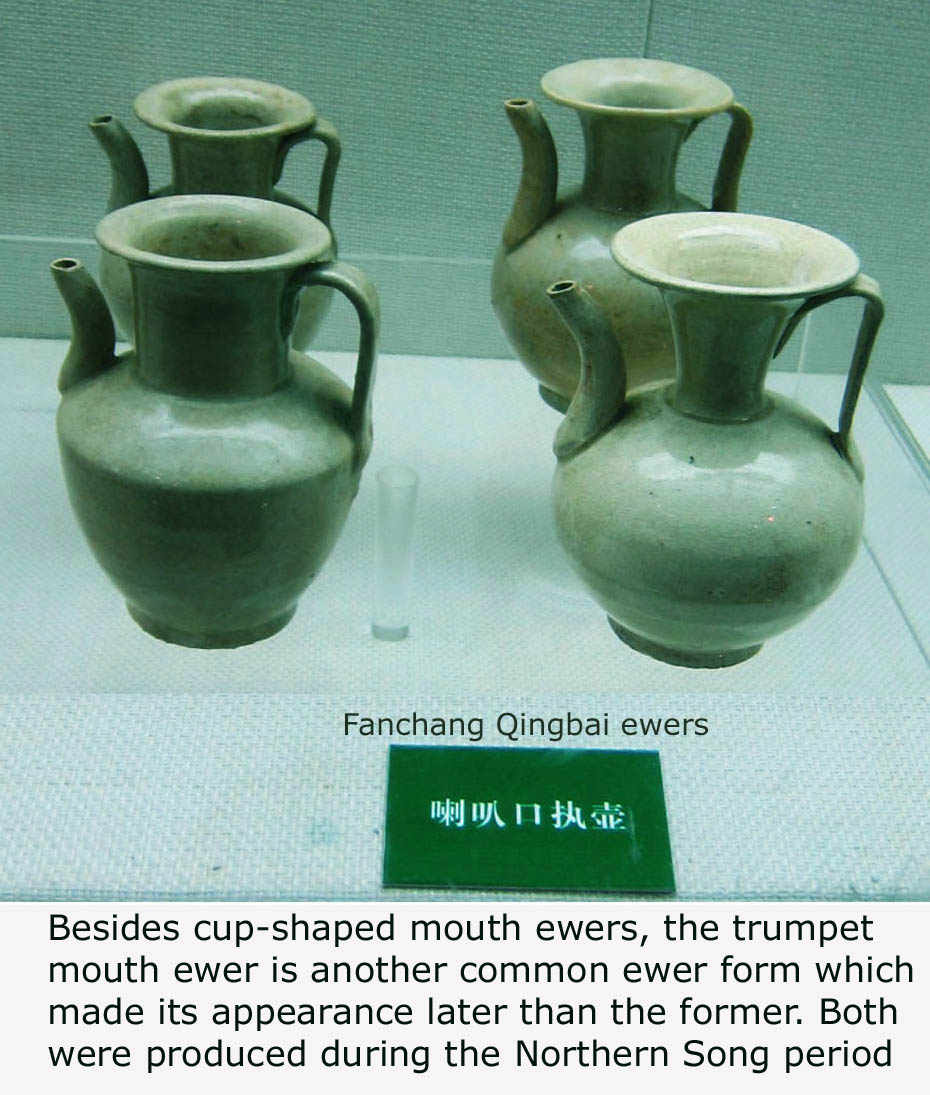

Ewer for tea drinking consisted of two form, one with dish-shaped and the other

trumpet mouth. The shape of the mouth provides a useful guide for dating.

For the former, those with a deeper dish shaped mouth were chronologically

earlier. They also have a shorter spout. As it evolved, the dish mouth

became shallower and the spout longer. They were first

produced sometime during the 5 dynasties period. For those with trumpet mouth,

those from the earlier phase have less flaring mouth. The

trumpet mouth ewer made its appearance only during the Northern Song period.

Both types were produced concurrently during the Northern Song period.

One of the most beautiful ewers found has a phoenix

head. It was identified by the

local ceramics expert as a product from Fanchang as it displays similar glaze and

paste characteristics of Fanchang ware.

Small bowl (Zhan) with stand is another interesting group of product from

Fanchang. The stand comes in two form, with a recess area or platform.

The platform on the stand which the zhan sits is low on typical Fanchang wares.

Those from Jiangxi Jingdezhen or Nanfeng has typically tall platform.

Fanchang only produced very small number with such tall platform. Both

the zhan and stand comes in plain or foliated form. The more elaborate

form has lotus petals carved in low relief on the body of zhan and platform of

stand. According to ancient text, zhan with stand was mainly used for tea

drinking.

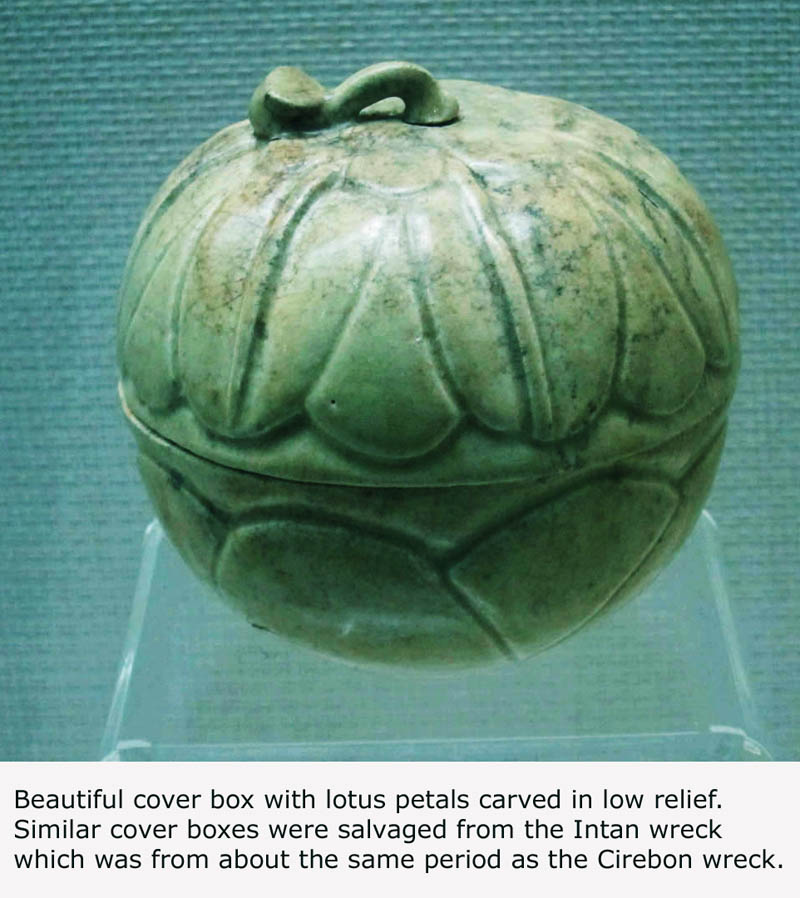

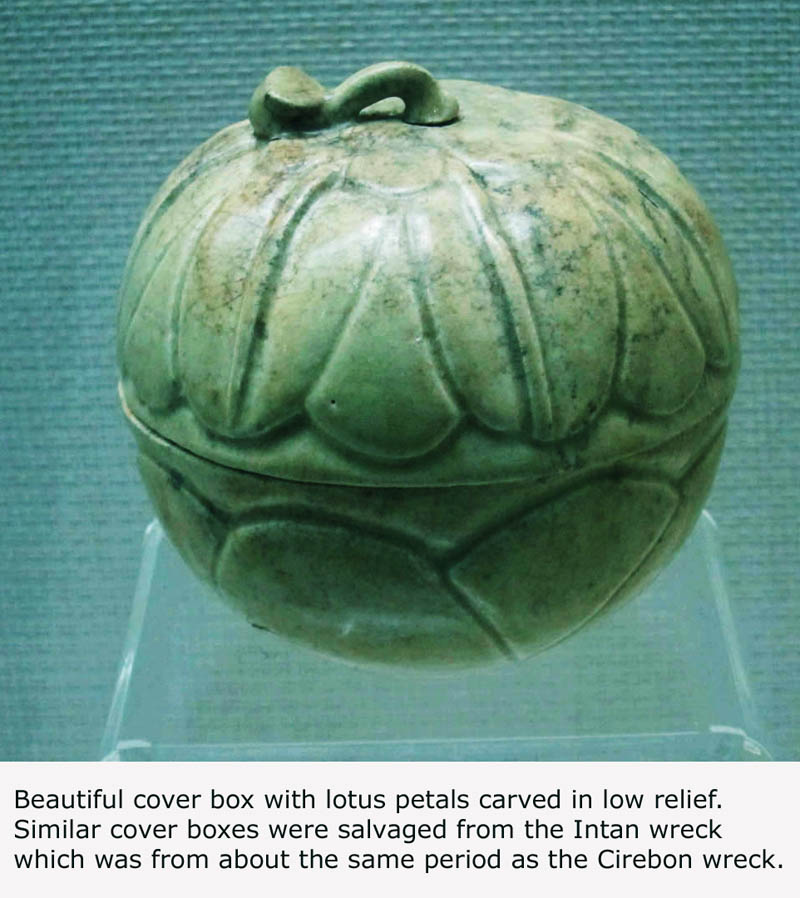

Fanchang potters also produced a wide varieties of cover

boxes. Those with tall elongated form were mainly used for aromatics

and the rest for cosmetics and oil. In the Intan wreck dating from early

Northern Song period, some qingbai cover boxes with lotus petals carved in

low relief were salvaged. They were similar to that produced in Fanchang

and could have originated from there.

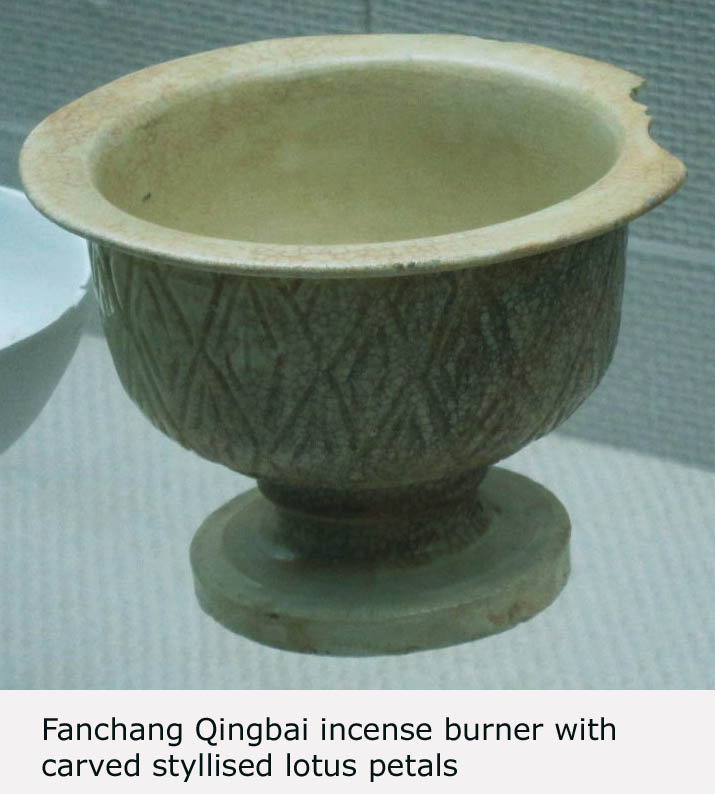

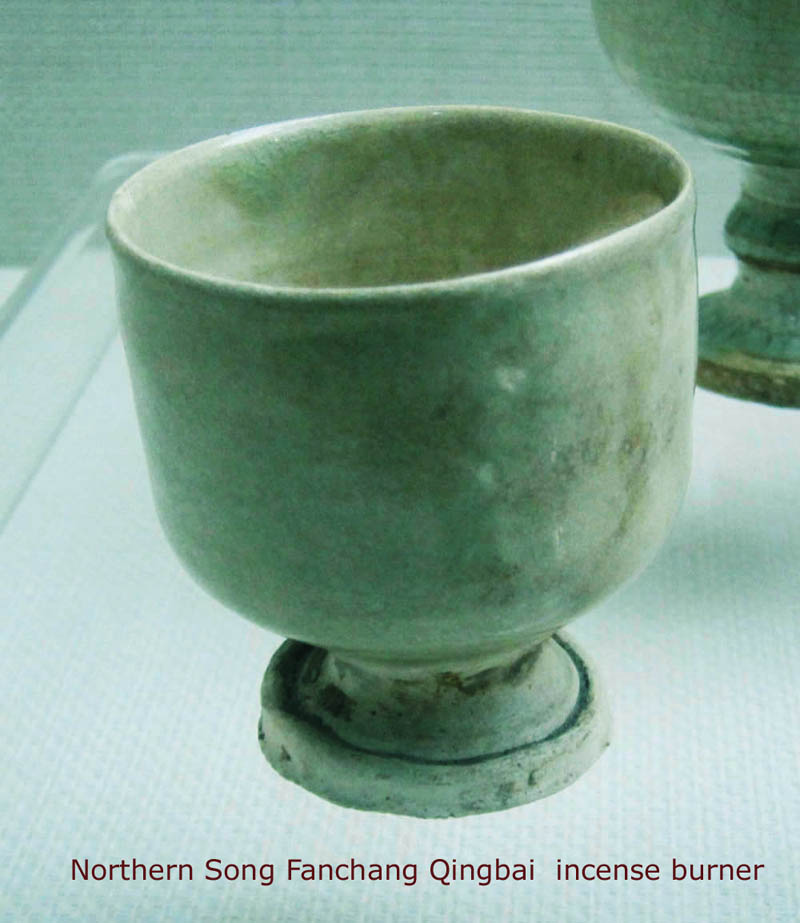

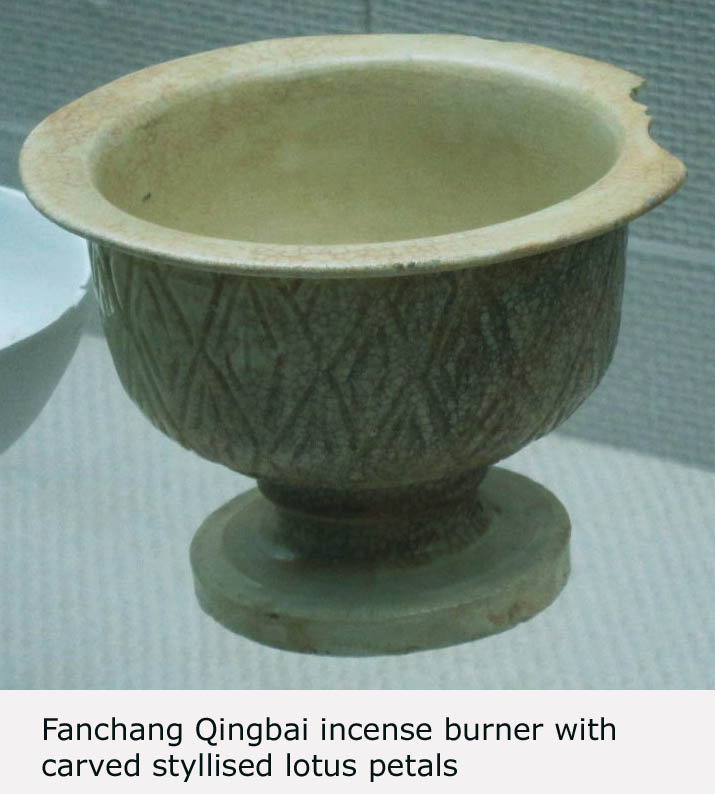

Incense burner was another popular product of Fanchang. The range of

variety was wide, majority simple plain form and the rest beautified further

with decorations such as carved lotus and/or open work. One of the most

impressive and large one using carving and open work technique is shown

below.

Vases and jars of various form and sizes constituted the last group of important

Fanchang products.

Written by : NK Koh (3 Mar 2016)

Reference: 繁昌青白瓷集粹 (繁昌县博物馆编著)