Qing Porcelain

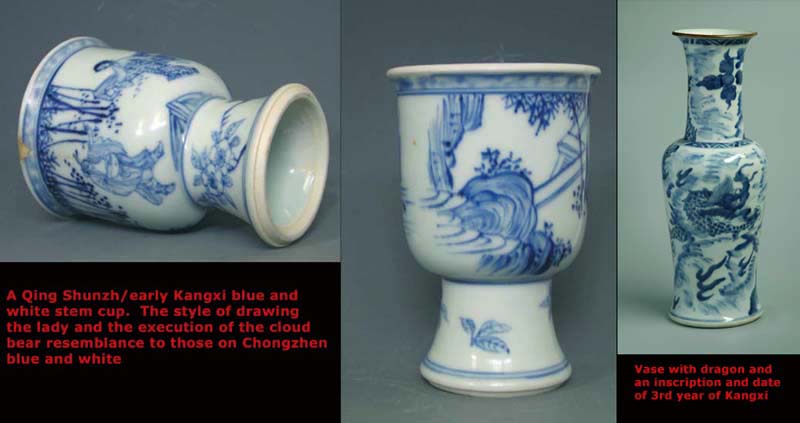

The porcelain production in Jingdezhen was adversely affected by the turbulence following the transition from Ming to Qing Dynasty and the destruction of large area of Jingdezhen during the Wusan Gui ( 吴三桂)rebellion in A.D 1675. During the Shunzhi period, there was small scale production of commissioned porcelains in the previous Ming Imperial kiln under the supervision of the local Jiangxi officials and imperial commissioners. The capability of the potters had deteriorated as evidenced by their failure to produce 200 large jars with dragon motifs. The items produced were mainly bowls, dishes, incense burners and small vases with underglaze blue, overglaze enameled decorations or monochrome glaze. Some pieces bear the Shunzhi reign marks. The decorative style of Shunzhi still shows influence of those produced during the Chongzhen period.

In A.D 1680 emperor Kangxi ordered a commission to look into the state of the porcelain industry in Jingdezhen. As a result, a re-organisation of the imperial kiln was carried out in A.D 1682 under the supervision of a court appointed superintendent Zang Yingxuan. Subsequent capable successors including Lang Tingji (Kangxi period) , Nian Xiyao (Yongzheng period ) and Tang ying (Yongzheng/Qianlong period) ensured the success of the Imperial kiln. (The administrative control of the imperial kiln was transferred to the local governor after the reign of Qianlong. The lack of close supervision and personal interests of subsequent emperors are probably the main reasons for the quality deterioration of the imperial wares since then). Personal interest of the emperors, especially Yongzheng and Qianlong who were involved in matters such as design of wares and comments on the quality of the works, also raised the quality benchmark. The old system of forced labour was replaced by paid craftsmen. Such a system had a spillover effects on the private kilns which also benefited from the transfer of the technology and skills. Hence, during the Kangxi/Yongzheng/Qianlong period generally good quality wares were produced for local consumption and export. It is generally recognised in the history of Chinese porcelain production as the epitome of technical perfection.

From the letters written in A.D 1712 and A.D 1722 by the French Jesuit missionary Pere d'Entrecolles,who made personally observations of the porcelain making process in Jingdezhen , we can gain some understanding of the ceramics production processes and the recipes for making the porcelain, glazes and enamels. The production process was based on a system of fine division of labour. Different persons were in charge of grinding the clay, throwing the vessels on the wheel, mixing glazes, applying decoration and firing the kilns. In the area of decoration, there was also fine distribution of duty. Different craftsman was in charge of drawing outline and completing the colouring of motif. The craftsmen also specialised on a particular motif, for eg. someone who draw human motif was not allowed to draw other motifs.

The rejuvenated Jingdezhen porcelain industry continued its dominance and was the undisputed porcelain production capital in China. It was during the reign of Kangxi/Yongzheng that important innovative decorative techniques for porcelains were introduced.

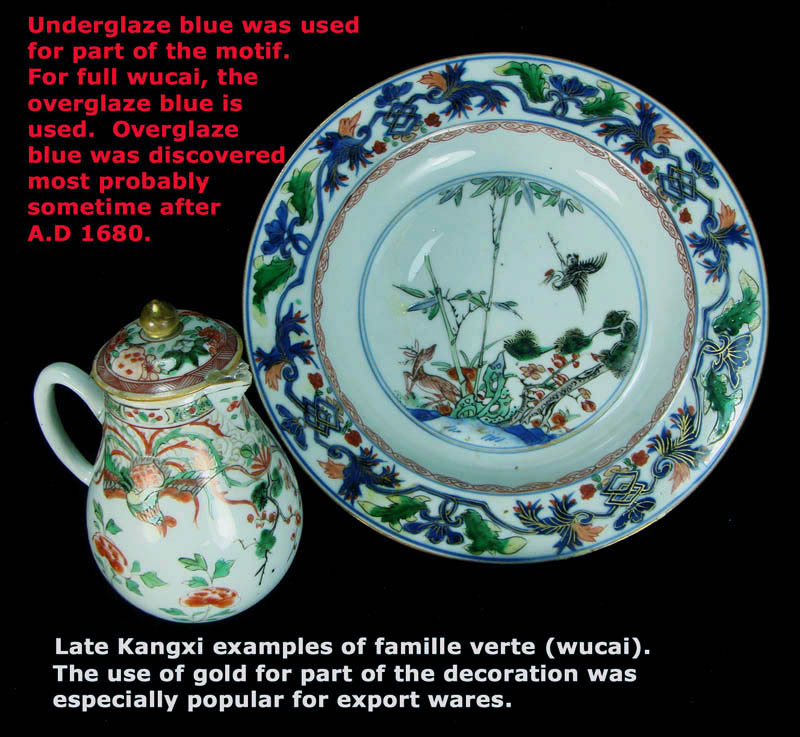

Wucai (famille verte)(五彩)

Wucai was an overglaze enameled decorative technique that was introduced since the Xuande period. During the early Kangxi period, there was still no overglaze blue. If blue is required, the under-glaze cobalt blue is used. In about A.D 1700 of the late kangxi period, overglaze blue enamel was introduced. According to Pere d'Entrecolles, the various wucai enamels consisted of 3 parts of white lead, one part of quartz and small amount of colouring oxide for the various colour. The blue was however pulverised blue glass that was also used as a glass enamel on metal work. Famille verte was coined by Jacquemart in the 19th century as the colour scheme usually has a dominance of green. Strictly speaking, famille verte wares should have the overglaze blue.

There is also a category of famille verte which the enamels are applied directly on biscuit. They included items such as teapot stands, incense burners, vases, ornamental panels for furniture, figurines and etc. Those with black or yellow ground has specific coined name, ie famille noire and famille jaune respectively.

There is also a category called susancai where different motifs are painted with different colour directly on the biscuit. The motifs are usually incised on the biscuit. It is called susancai as only neutral colours such as yellow, green, purple and etc are used. The strong colour red is absent from such pieces.

Falangcai

(

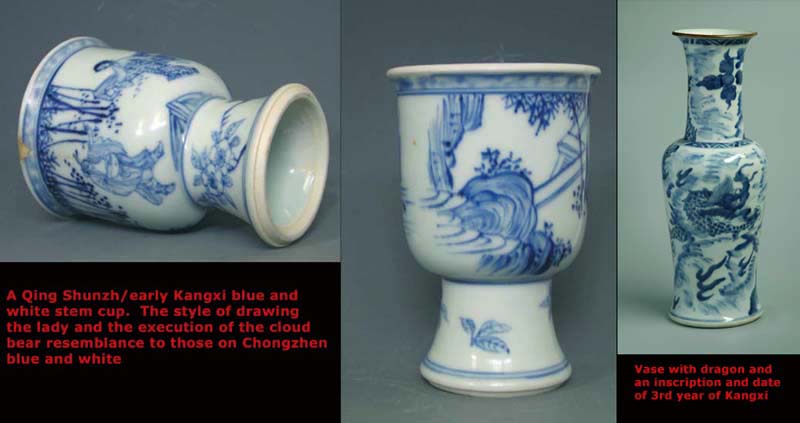

During the 32nd year of Kangxi reign, workshops were set up in the Yangxin Hall (养心殿) in the palace to produce various form of artcrafts. One of the workshops was called falang Zuo (珐琅作), initially dedicated to produce bronze cloisonne vessels decorated using enamels imported from Europe. In the 55th year of Kangxi, the workshop started experimenting with production of falangcai on porcelain. Plain porcelain vessels were ordered from the Imperial kiln. The porcelain surface which required enameling is unglaze in biscuit form. After the vessel is decorated with enamels, it is fired in muffle kiln in the Palace workshop. Apparently, during the experimental stage, the potters were still unable to overcome the technical problem of completing the decoration on glaze surface. The main problem encountered is related to the different expansion/contraction rate of the enamels and the porcelain medium. In fact, the enamels of Kangxi falangcai are characterised by very fine crazings. The raw enamels are in soft glass form and is also called liaocai (料彩), ie glass colour in Chinese. There are only about 40 pieces of extant Kangxi falangcai vessels.

The enamels were initially imported from Europe but in the 6th year of Yongzheng (1728 A.D), the Chinese succeeded in producing the enamels and even introduced additional colours.

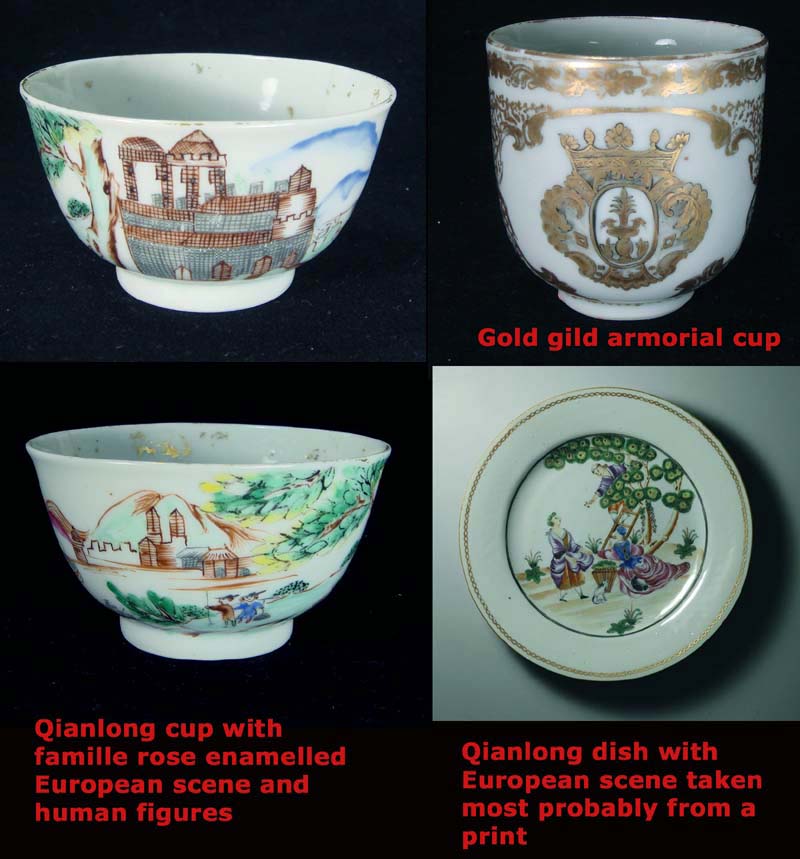

During the Kangxi period, the wares has a coloured ground imitating the cloisonne form, the favourite colour being red and yellow. The base has the overglaze enameled mark Kangxi Yuzhi (康熙御制). During Yongzheng period, more varieties of decorations were introduced. The decoration is drawn on glazed surfaced instead of the unglaze surface during Kangxi period. They include floral/bird and landscape motif accompanied by poetic inscription and seal marks. During the Qianlong reign, there were even those decorated with European style human subjects.

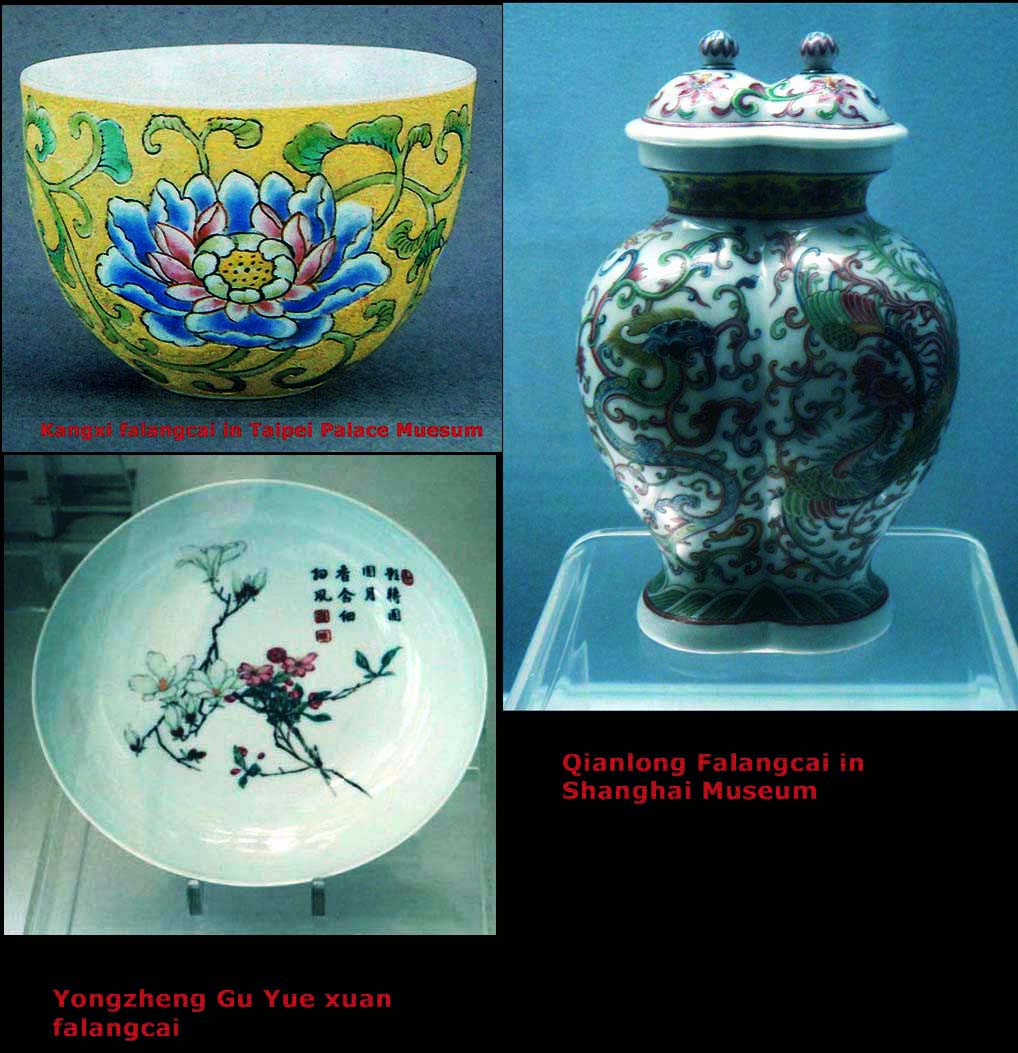

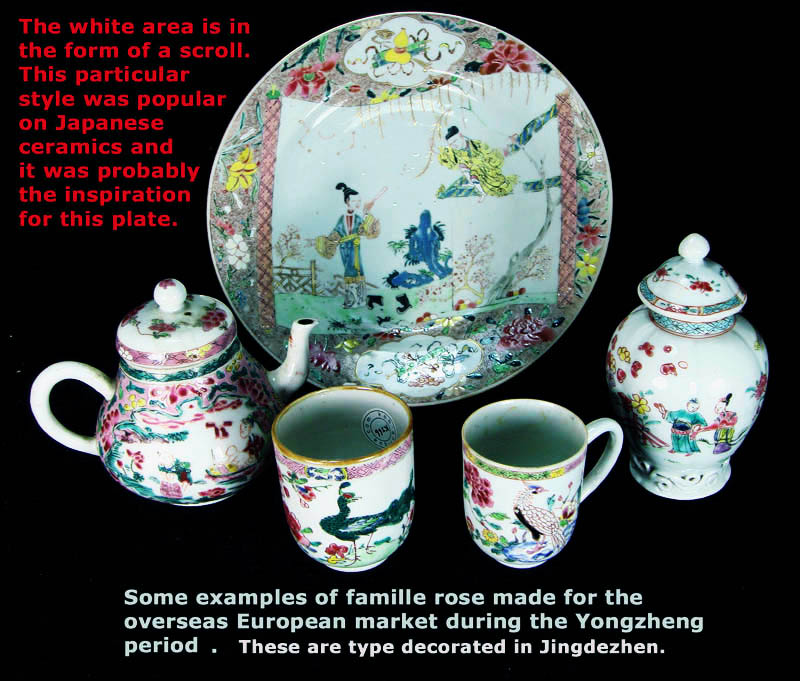

During the late Kangxi period, the Jingdezhen and imperial kilns began the production of a hybrid overglaze enameled wares which incorporate enamels of falangcai and wucai. The term Yangcai was used by the Imperial kiln superintendent Tang Yin to describe this type of overglaze enameled ware. In the late Guangxu period, the term fencai (粉彩) and ruancai (软彩) was used for Yangcai as the enamels looks soft and has powdery texture. The enamels looks different from wucai, which are more transparent/semi transparent and hard-looking in appearance. The term yingcai (硬彩), ie hard colour] was an alternative term for wucai. In Europe, the term famille rose was used to describe the fencai wares. It was coined in the 19th century by Jacquemart as a colloidal gold rose pink colour dominates the fencai decoration.

Fencai acquires the opaque or powdery look due to the presence of a substance called po li bai (玻璃白),an opaque lead-arsenate white enamel. The shading effect ,which gives perspective to a motif, is achieved by altering the ratio of colored enamels to this white enamel. A typical example is that as applied for the pink floral petals. Another distinguishing enamel is the opaque yellow which is visually different from the more transparent iron yellow of wucai. According western chemical analysis conducted, stannic oxide (氧化锡)is present, and the enamel is identified as derived from lead stanate However, there is deviation in the view on the source of this new yellow from the Chinese chemical analysis of the yellow enamel. Antimony oxide (氧化锑) is identified as the colourant.

Fencai became the most popular overglaze enameled wares for local and overseas market since the Yongzheng period. The quality of fencai enamels also deteriorated especially from Daoguang period onward. The enamels tends to be applied more thinly and lack the glossiness of the earlier period.

For more detailed discussion on the relationship between falangcai, yangcai and fencai, please read this article.

A variant of fencai, called Qianjiang became very popular from the Tongzhi to republican period. The elegant color scheme include sepia and pale umber, and smaller amount of other colour such as aquamarine, moss green, pale blue and light pink. This is similar to a type of Qianjiang landscape on paper/silk developed by Yuan painter Huanggong Wang. It is in effect a literati form of painting on porcelain. The motif of Qianjiang is drawn by an artist and usually has a poetic inscription. The pioneers of Qianjiang paintings are Cheng men (程门), Wang shaowei 王少维)and Jin Pin Qing (金品卿). This is different from the other type of decorations which involves division of labour. This literati approach has a great impact and influence on the new fencai of the Republican period. For more, please read this section on Qianjiang porcelain.

Qianjiang Landscape by Jin Pin Qing

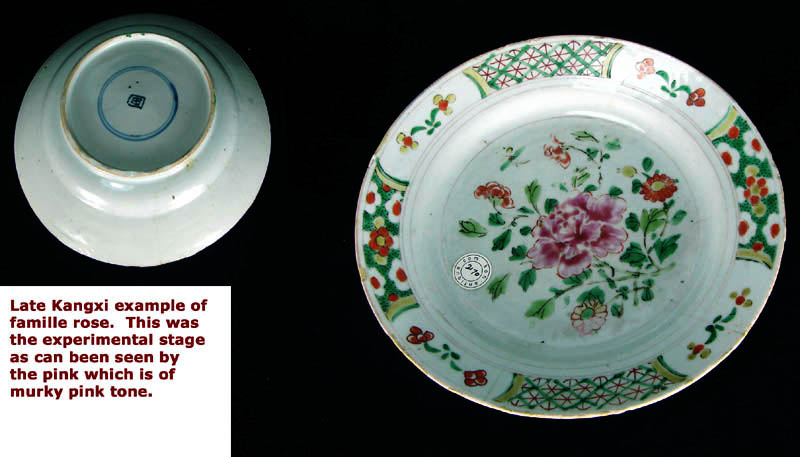

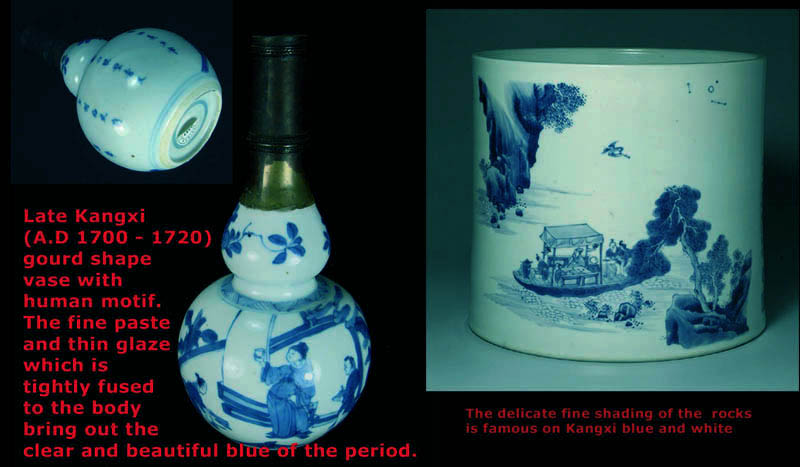

Blue and white

Kangxi period blue and white is famous for the very fine and delicate shading of the rock/mountain for landscape painting. The refined glaze of Kangxi period thinly fused well with the biscuit. Together with superior preparation for the highly refined cobalt, it gives the famous sapphire blue. There is generally no blurring of the blue and the lines are well-defined. This characteristics gives an attractive crisp outline and clear wash of blue found in human subjects which were usually copied from block-prints novels and instruction books for drawing of motifs for Chinese paintings.

For imperial blue and white since Kangxi period, most continued to copy the floral scrolls motif of the much admired Yongle/Xuande period. The heap and pile effects which is natural on Ming pieces, is created by doting the required areas with higher content cobalt pigment. The heap and piles lack the randomness of the Ming pieces and does not sink into the biscuit and lack the metallic sheen found in the Ming pieces.

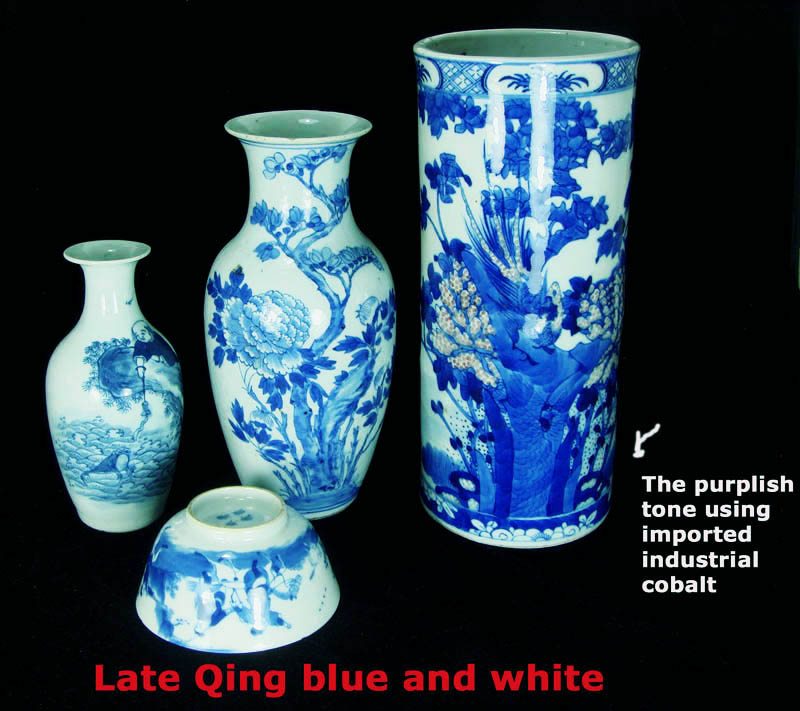

The quality of blue and white deteriorated from the late Qianlong period. The cobalt of mid Qianlong onward tends towards a darkish blue tone. The late Qing blue generally appears to float in the glaze as compared to the earlier period which appears to seat below the glaze. The blue also appeared to be fragmented and not smooth looking. Some part of the blue outline also tends to appear lighter or missing. There is one article which discusses about this hollow line effect and the author suggested that it is a characteristic to determine late Qing blue and white. This is generally true but there are always exceptions. A more comprehensive approach should also include the following factors:

All the above points, except the last point, can only be more clearly understood by physically handling many pieces. It can appear abstract to those new collectors.

During the late Qing, probably from Guangxu period onward, there are also blue and white wares decorated with a form of imported industrial cobalt. The blue has a purplish and unpleasant glaring look.

Underglaze copper red

During the Kangxi period, underglaze copper and underglaze cobalt blue/copper red were fully mastered. The red achieved is good and the red outline of the motif is clear and crisp. This is not an easy achievement as copper red is a highly volatile pigment and hard to control. The colour could become very light or greyish/darkish red or totally dissipated without good mastery of the preparation of raw materials and firing of such wares. The potters' understanding of application of the pigment is so thorough to the extend that certain part could be rendered the oxidising green color at will such as shown for the cloud enshrouding the below dragon. Good quality copper red pieces continued to be produced till Qianlong period. After that, the quality of the red deteriorated and are usually more greyish red in colour.

Monochrome Glazes

During Kangxi period, the technology for making monochrome copper red (first made during early Ming period but the recipe lost since the mid Ming period) was re-disovered. Two famous types fired successfully are Langyao red and sacrificial red. Creation of the Lanyao red is credited to Kangxi Imperial kiln superintendent Lang Tingji. The glaze looks like newly congealed ox blood and is called sang de boeuf in the western world. The glaze is more glassy than the sacrificial red and has crackles on the glaze surface. The base is usually a millet yellow or light greenish tone. The control of the flow of the glaze is excellent during Kangxi period and seldom run off the foot. Those of the later Qing period tends to run off the foot and stuck to the kiln support. Majority required the over-run glaze to be filed off.

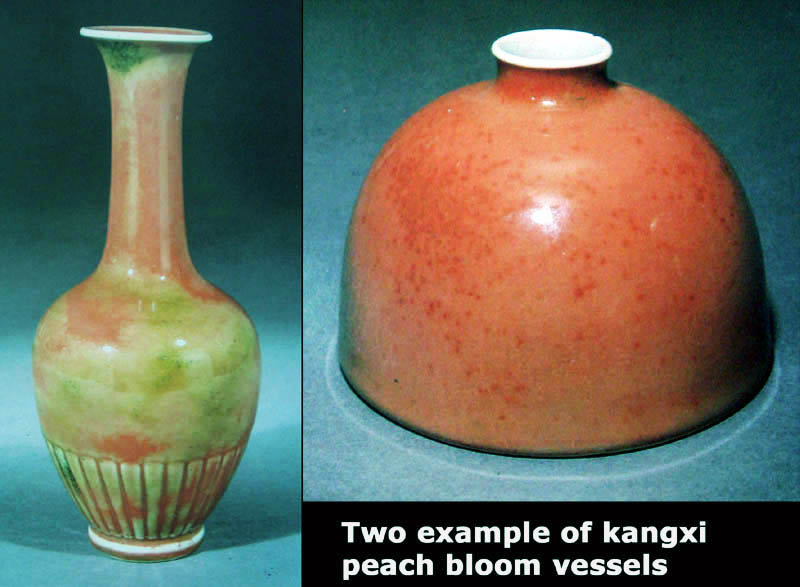

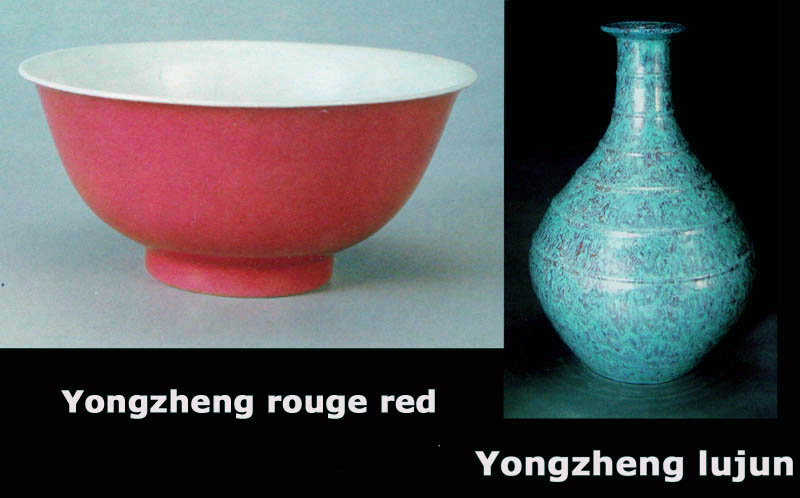

Other variants of monochrome red are the Kangxi peach bloom glaze and Yongzheng Jun red. The peach bloom glaze has a powdery look. The glaze is blown on the biscuit through a bamboo tube covered with gauze at one end. Majority has area covered with orange, yellow and green specks. There are also those which are oxidised green.

The Jun glaze creates the effect of the Song Jun. The base red glaze is mottled with bluish/moon white glaze. Other interesting monochrome are high fired Yongzheng iron teadust glaze, Kangxi powder blue and mirror black (乌金釉). The cobalt powder blue and the mirror black wares are usually decorated with gold motifs. For the mirror black, besides iron, the glaze also contains cobalt and manganese. Besides those mentioned, there are also imitation of ge, ru and celadon glaze and the popular blue glaze.

In the area of low fired monochrome, coral red, rouge red (胭脂红)/rouge water (胭脂水)and lujun (robbin egg) glaze are the most famous. The coral red is an iron glaze with tinge of orange resembling the colour of coral. The rouge red/rouge water used the colloidal gold as the colourant for the glaze. The lujun glaze is a low fired version of the Jun glaze. The best lujun has red spots in the streaks. The lesser quality has blue spots. Other low fired monochrome includes yellow, green and turquoise glaze.

Export porcelains

After about A.D 1680, the European traders resumed their active purchase of porcelains after the kilns in Jingdezhen undergone re-organisation and again able to produce quality porcelains .

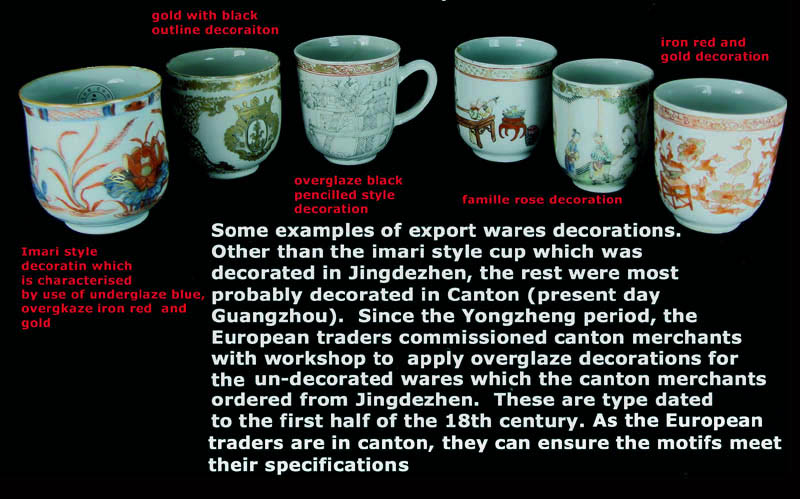

During the Kangxi period, blue and white and famille verte palette were the main medium for decoration for export porcelains. Some of the export wares are not distinguishable from those used locally. However, there are also those which are clearly made for export. The motifs used are essentially the same. But the composition such as those for the plate/dish, is crowded. They usually include panels on the rim which are reserved for additional motifs. There are also wares with obvious European shape. Some limited use of design from European prints and also armorial wares were also made.

18th Century Armorial wares

|

|

|

Some common features of export wares of the Kangxi/Yongzheng period could be gathered from wares recovered from the Vung Tau and Ca Mau Shipwreck.

Canton (Guangzhou 广州)was the designated port which Europeans were allowed to conduct business with China. The breakthrough came in A.D 1699 when Kangxi emperor permitted the English to acquire the goods (mainly tea and porcelain) in Canton for shipment back to England on the ship Macclesfield. The English was the first to set up factory (Hong) in A.D 1715 on the land (outside the Canton city wall) along the river pearl. By the 2nd half of 18th century, a row of factories each flying the flag of a European country- English, Dutch, French, Swedish, Danish, American, etc, were built. The scene with the factories along the river was a popular design found in especially punch bowls done in famille rose palette. Those were rented premises which the European traders stocked the good for sale and also their purchases. The traders were only allowed to trade through authorised Hong merchants from the co-Hong, an Association empowered by the court to deal with foreign traders . The Hong merchants were responsible for the conduct of the foreigners. Business was conducted for the period around June to January. After which, the foreigners were required to leave Canton. For those not returning to Europe, they could stay at Macau.

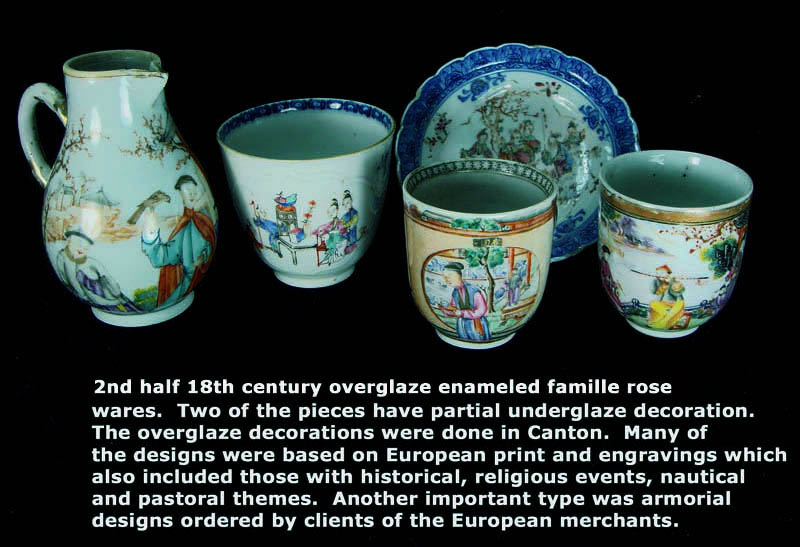

Increasingly the European consumers were demanding porcelains decorated with European themes, especially those found in prints from engravings by European artists. They include pastoral European scenes, religious themes such as crucifixion and Resurrection of Lord Jesus, historical events such as riot of Rotherdams and nautical scene of ships sailing in sea, engaged in battle or in harbour. Another popular theme showed Chinoiseries decorations, such as European perceived chinese human characters engaging in various domestic activites. Another important category is armorial wares for dinner and tea service. They consisted of vessels such as dishes, plates, tureens, salts and etc.

Armorial wares were first made in Jingdezhen in underglaze blue or famille verte palette. It is not uncommon to find the motif drawn incorrectly such as wrong lettering and colour. The subsequent popularity of famille rose palette decoration enable the problem to be resolved. Workshops were built in Canton with facilities to draw overglaze decorations. The typical workshop had its team of enamellers and muffle kilns to fire pieces at about 900 degree to fix the enamels. The workshops were stocked with porcelains in various forms either plain or partially decorated with underglaze blue decoration. The proximity of the workshops enabled the Europeans to supervise the drawing of motifs and ensured they followed closely samples provided.

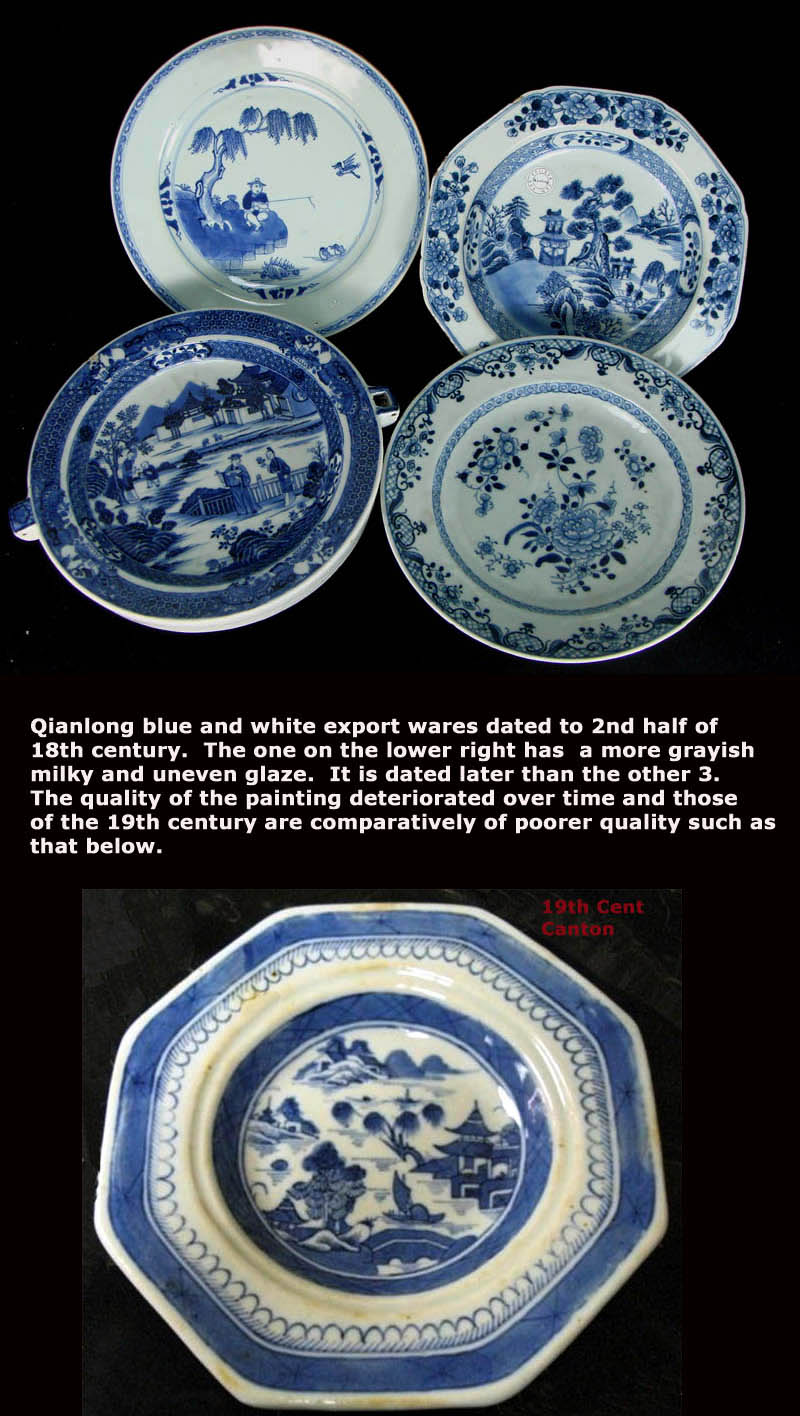

This wave of export trade peaked in about A.D 1750 but continued to be significantly active through to the end of 18th century. The Dutch and the English were the most important importers. During the late 18th and the 19th century, the American took over as the major importer of Chinese porcelain. Those blue and white dishes/plates from A.D 1760 onward usually have elaborately decorated band on the rim such as that shown in the lower two plates of the below photo. Blue and whites shown in below photo are usually termed Nanking wares in the Western world.

The main reason for the decline in the export Chinese porcelain was the competition posed by the production of porcelain wares by the European porcelain factories and subsequent Staffordshire pottery with underglaze transfer print Chinoiseries decoration such the willow type landscape. The low cost and mass-produced Staffordshire blue also began to displace the Chinese porcelain in America after A.D 1820. Another main reason for the decline in export Chinese porcelain was the overall drop in its quality after the 18th Century. The porcelain of the late 18th century tends to be more crude with uneven glaze and deteriorating standard of the drawing. During the Mid 19th century, a type of famille rose decoration with Mandarin and/or Rose patterns became popular. Rose medallion refers to type with a centre medallion with floral/bird motif surrounded by panels decorated with either birds/florals or human motif. Canton rose refers to those with solely birds/flowers motif. Rose mandarin consisted of human motif. The main characteristics of such wares is the prevalence of roses and the foliage enclosing the the panels in the design composition.

|

|

|

Export Dehua porcelains

During the late Ming period, Dehua started exporting a large varieties of white wares: cups, censers, gu-vases, ewers, bowls, large plates, lamp, seated lions, figurines. These white wares are called Blanc de chine. Such wares have a silky ivory white tone and the porcelain is translucent. From the 17th/18th century, many Dehua blanc de chine were exported to Europe. Dehua Blanc de chine attracted considerable favourable responses in Europe and were widely collected by royal families and nobles. Those from the Early Qing period still retained the ivory tinge glaze but the later Qing pieces became a less attractive more grayish white tone. Hence, the demand for them declined in the mid/late Qing period.

During the 18th/19th century, Dehua kilns also exported many blue and white wares to cater to clients mainly in Southeast Asian countries. Dehua blue and white developed their own distinctive characters during the Qianlong period and were widely copied in Fujian/Guangdong region.

Blue and white wares found in the Tek Sing cargo (dated A.D 1822, 2nd year of Daoguang reign), may serve as reference to study characteristics of wares of late Qianlong/Daoguang period. It is clear that by then, Dehua blue and white has firmly developed their unique characteristics and different from their Jingdezhen counterpart. Dehua wares are more thickly potted and has a distinctly more opaque and thick glaze as compared with the Jingdezhen wares which are more thinly potted and has a thinner and more transparent glaze. Most of the bowls and plates has the name of shop/factory (such as 合记, 全记, 月记, ,全兴,源利,合珍) or promotional-like wordings praising the product (such as 玉,胜玉, 同玉, 吉玉, 美玉) written on the outer base

Example of Dehua Blue and white

For more, please read : Dehua blue and white.

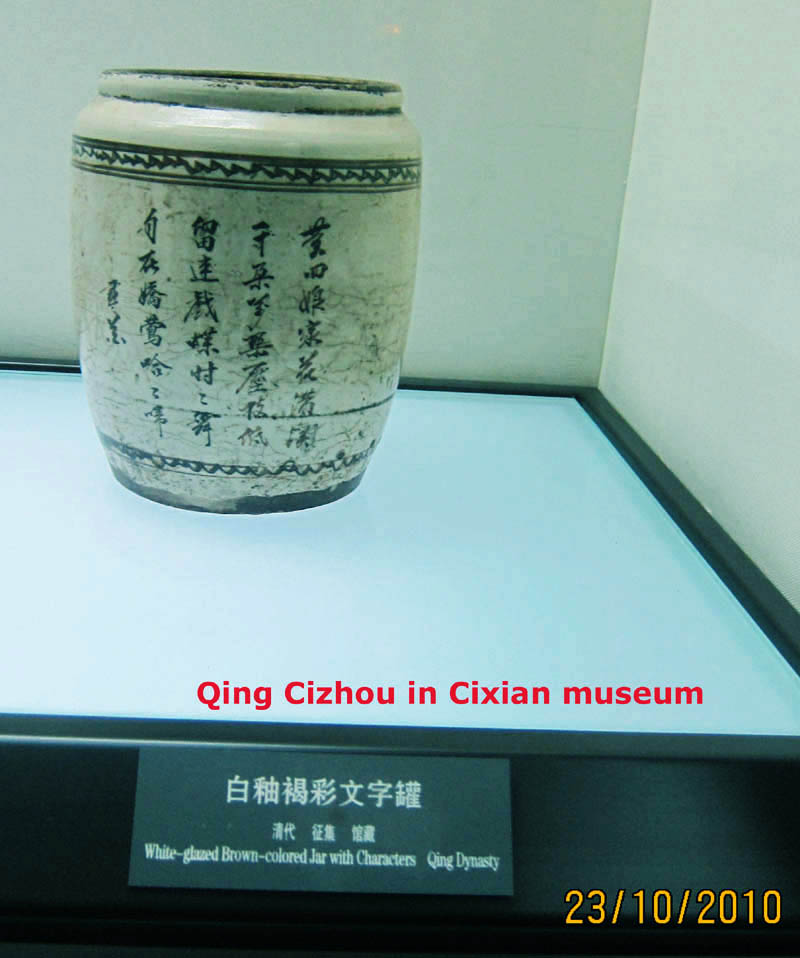

Hebei Cizhou porcelains

Pengcheng in Hebei continued to produce Cizhou type iron brown decorated porcelains during the Qing Period. It continued to be an important source of porcelain wares for domestic consumption in Northern China. However, due to the popularity of blue and white, it switched to blue and white as its main production during the late Qing period. Some of the blue and white produced by some of the better potters were of good artistic quality. There is a category which followed the literati style of drawing and has inscription and name of the artist. In terms of standard, some of the works are comparable to the good ones from Jingdezhen. However, due to the application of a slip over the vessel before decoration as in the past, the the blue and white tends to have poorer adhesion and flakes more easily.

Decline in the porcelain industry after Qianlong

The extravagance of Qianlong emperor exacted a severe strain on the finance of the empire. The power of the Qing empire declined from Jiajing period onward. This is also reflected in the deteriorating quality of porcelains. The destruction of Jingdezhen by the Taiping rebels in A.D 1853 during the Xianfeng reign had a particularly devastating effect on the porcelain industry. Although the imperial kiln was revived during the Tongzhi period, the general standard of the porcelains could not recover its previous glory. A bright spot was the revival of blue and white during the Guangxu period when good copies of the Kangxi blue and white were produced. The Qianjiang porcelain mentioned earlier was another important innovative decorative technique which greatly influenced the production of the high quality and artistic new fencai paintings during the Republican period.

Written by: NK Koh (2 Apr 2010) Updated (26 Nov 2010)

References

1 Chinese ceramics - The new Standard Guide by He Li

2 Oriental Ceramics at the Cape Of Good Hope 1652-1795 by C Woodward

3 History of Chinese Ceramics by Masahiko Sato

4 The Chinese Potter by Margaret Medley